The Lycoming O-320 engine is a popular choice in general aviation, powering a wide range of light aircraft, such as the Cessna 172 and Piper PA-28 Cherokee. Known for its durability and reliability, this four-cylinder, horizontally opposed engine delivers dependable performance for pilots and aircraft owners alike.

A critical component of the engine’s functionality is its firing order, which ensures smooth operation and balanced power output.

In this guide, we’ll explore the firing order of the Lycoming O-320 engine, why it matters, and how it contributes to the engine’s overall efficiency. Whether you’re a pilot, mechanic, or aviation enthusiast, this article will provide a clear and focused understanding of this critical engine detail.

Quick Navigation

The Lycoming O-320 Firing Order

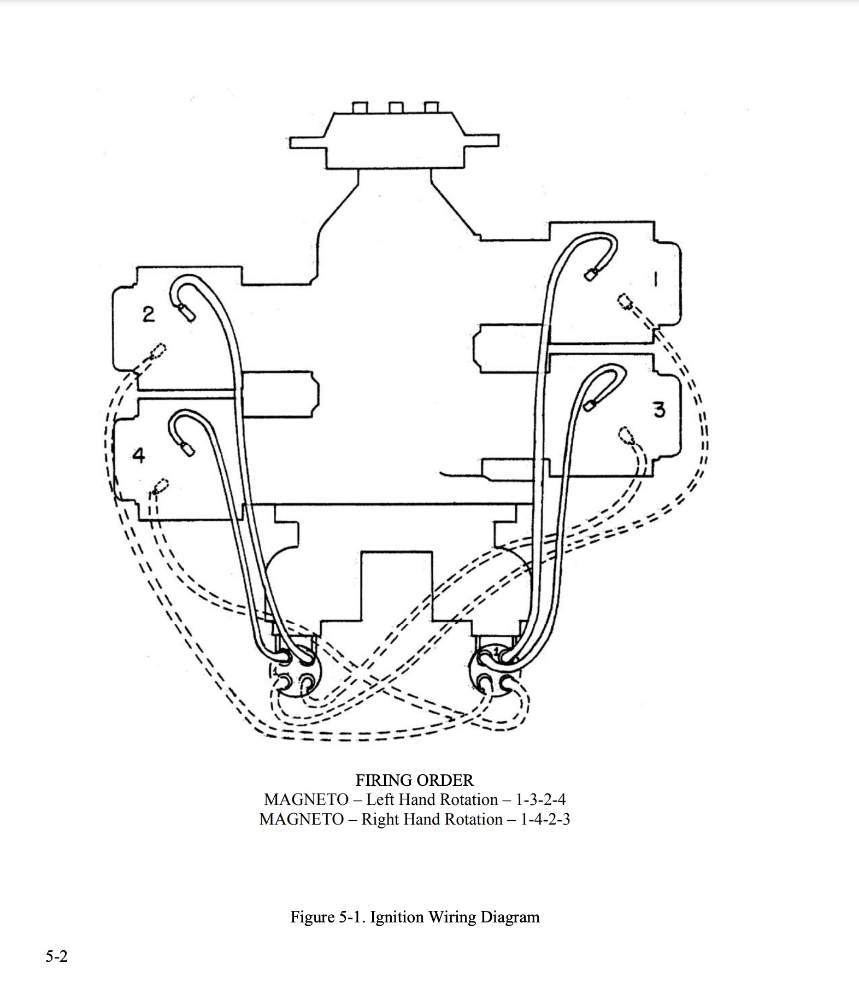

The firing order for the Lycoming O-320 engine is: 1-3-2-4

How the Firing Order Works

- Cylinder 1 Fires First: The frontmost cylinder on the right bank initiates the combustion process.

- Cylinder 3 Fires Next: The rear cylinder on the right bank fires second.

- Cylinder 2 Fires Third: The front cylinder on the left bank ignites next.

- Cylinder 4 Fires Last: The sequence ends with the rear cylinder on the left bank, completing the cycle.

This firing order alternates between the left and right banks of the engine, maintaining balance and smooth operation.

Why Lycoming Uses the 1-3-2-4 Firing Order

The 1-3-2-4 firing order is designed specifically for the O-320’s horizontally opposed layout to achieve the following:

- Balance: Alternating ignition between banks reduces vibrations and ensures a stable operation.

- Efficient Power Delivery: Ensures continuous power generation without interruption.

- Smooth Operation: Minimizes engine stress and prevents excessive wear on the crankshaft and connecting rods.

- Reliable Combustion: Optimized timing allows the air-fuel mixture to burn completely, enhancing fuel efficiency and power output.

What Is a Firing Order?

The firing order is the sequence in which an engine’s cylinders fire or combust the air-fuel mixture. In a four-stroke engine like the Lycoming O-320, this firing process occurs in a specific order to maintain balance, reduce vibrations, and ensure consistent power delivery.

Why the Firing Order Is Important

- Smooth Engine Operation: Proper sequencing minimizes vibrations, allowing the engine to run smoothly.

- Performance: Balanced combustion ensures consistent power output for optimal performance.

- Efficiency: Accurate timing promotes complete combustion, improving fuel efficiency.

- Longevity: A well-timed firing order reduces stress on internal components, extending the engine’s lifespan.

Overview of the Lycoming O-320 Engine

The Lycoming O-320 is a four-cylinder, horizontally opposed, air-cooled engine with a displacement of 320 cubic inches. This engine is widely used in general aviation due to its robust design, simplicity, and ease of maintenance.

Engine Configuration

- Horizontally Opposed Layout: Two cylinders on each side of the engine, positioned opposite one another.

- Air-Cooled: Relies on airflow to regulate engine temperature during operation.

- Four-Stroke Cycle: Operates on intake, compression, power, and exhaust strokes.

- Cylinder Numbering:

- Right Bank: Cylinders 1 and 3 (front to back).

- Left Bank: Cylinders 2 and 4 (front to back).

Identifying the Firing Order

Understanding and verifying the firing order is critical for maintenance, tuning, and troubleshooting. Here’s how you can identify and confirm the firing order for the Lycoming O-320 engine:

Check the Engine Manual

The engine manual provides detailed specifications, including the firing order and cylinder numbering. It’s an essential resource for mechanics and aircraft owners.

Locate Cylinder Numbers

Cylinder numbers are often stamped on the engine block or visible near the spark plugs, making it easier to identify the correct sequence.

Use Timing Tools

Crankshaft and magneto timing marks can help confirm the ignition sequence during maintenance or repairs.

Symptoms of Incorrect Firing Order

If the firing order is incorrect, the engine will exhibit several performance issues that can impact safety and efficiency. Here are the most common symptoms:

Common Symptoms

- Engine Misfires: Irregular firing disrupts the combustion process, leading to uneven power delivery.

- Rough Running: The engine vibrates excessively or feels unstable during operation.

- Power Loss: Disrupted combustion reduces overall power output, affecting performance.

- Increased Fuel Consumption: Inefficient combustion causes higher fuel usage and increased emissions.

- Overheating: Misfiring cylinders can lead to excessive heat buildup, risking engine damage.

Causes of Incorrect Firing Order

- Misconnected Spark Plug Wires: Spark plug wires routed to the wrong cylinders disrupt the firing sequence.

- Faulty Magneto Timing: Improperly timed magnetos can throw off the ignition order.

- Worn Components: Damaged spark plugs, magnetos, or ignition leads can interfere with proper timing.

Diagnosing and Fixing Firing Order Problems

If you suspect issues with the firing order in your Lycoming O-320 engine, follow these steps to diagnose and resolve them:

Diagnostic Steps

- Inspect Spark Plug Wires: Ensure that each wire is connected to the correct cylinder according to the 1-3-2-4 sequence.

- Check Magneto Timing: Verify the timing alignment between the crankshaft and magnetos.

- Perform a Compression Test: Check for adequate compression in all cylinders to ensure proper combustion.

- Use a Timing Light: Confirm ignition timing and compare it with manufacturer specifications.

Fixing Common Issues

- Reconnect Spark Plug Wires: Ensure wires are routed to their corresponding cylinders in the correct order.

- Adjust Magneto Timing: Align the magnetos with the crankshaft timing marks for accurate ignition.

- Replace Faulty Components: Install new spark plugs, ignition leads, or magnetos if they are worn or damaged.

Preventative Maintenance for Firing Order Reliability

Maintaining the correct firing order is vital for the Lycoming O-320 engine’s long-term performance. Here are some preventative measures:

Regular Inspections

- Check the condition of spark plugs, ignition leads, and magnetos during routine maintenance.

- Look for wear, corrosion, or loose connections.

Replace Components as Needed

- Replace spark plugs and ignition wires at intervals as Lycoming recommends.

- Use OEM parts to ensure compatibility and reliability.

Verify Timing Regularly

- Periodically check and adjust magneto timing to maintain accurate ignition sequencing.

- Perform timing inspections during scheduled maintenance or after significant repairs.

Engines with Similar Firing Orders

FAQs About the Lycoming O-320 Firing Order

Can I Change the Firing Order?

No, the firing order is fixed by the engine’s design and crankshaft configuration. Altering it would require significant modifications.

What Happens If the Firing Order Is Incorrect?

An incorrect firing order can cause engine misfires, power loss, rough operation, and potential damage to internal components.

How Can I Verify the Firing Order?

Refer to the engine manual, inspect cylinder markings, or use timing tools to confirm the ignition sequence.

Is the Firing Order the Same for All Lycoming Engines?

No, while many Lycoming engines share similar firing orders, variations exist depending on the model and configuration.

Conclusion

The 1-3-2-4 firing order is a fundamental aspect of the Lycoming O-320 engine, ensuring smooth operation, balanced power delivery, and efficient combustion. Understanding this firing order is essential for maintaining and troubleshooting the engine, as well as ensuring safe and reliable flight performance.

By following preventative maintenance practices and addressing issues promptly, you can ensure that your Lycoming O-320 engine continues to deliver the dependable performance it’s known for in general aviation. Whether you’re a pilot, mechanic, or enthusiast, understanding the firing order is a critical step in mastering this trusted engine.