The Mopar 360 engine, a member of Chrysler’s LA-series small-block V8 family, is a reliable and versatile powerplant. Commonly found in Dodge trucks, muscle cars, and other vehicles, it has earned a reputation for durability and performance.

A crucial aspect of its operation is the firing order, which determines how the engine’s cylinders ignite their air-fuel mixture. This guide will provide a clear understanding of the Mopar 360 firing order, its role, and tips for maintaining it.

Quick Navigation

What is a Firing Order?

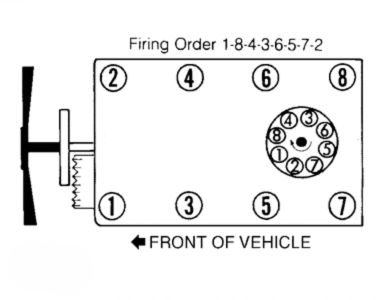

The firing order refers to the sequence in which an engine’s cylinders ignite during the combustion process. For the Mopar 360, the firing order is 1-8-4-3-6-5-7-2. This sequence ensures balanced operation and efficient power delivery.

A proper firing order prevents issues like misfires, uneven performance, and excessive engine vibration. Let’s explore why this specific order is important for the Mopar 360.

Why the Firing Order Matters

The firing order plays a critical role in how the Mopar 360 operates. Here’s why it’s essential:

- Engine Balance: Proper sequencing distributes power evenly, reducing vibrations and enhancing stability.

- Power Delivery: The firing order ensures continuous torque, leading to smoother acceleration.

- Efficiency: Correct ignition timing promotes complete combustion, optimizing fuel economy and reducing emissions.

- Longevity: Balanced operation minimizes wear and tear on engine components, improving durability.

- Performance: The firing order helps the engine run smoothly, providing reliable power under all conditions.

An incorrect firing order can cause misfires, power loss, and potential damage to the engine.

The Mopar 360 Firing Order: 1-8-4-3-6-5-7-2

The Mopar 360 engine follows the firing order 1-8-4-3-6-5-7-2. Let’s break it down step by step:

- Cylinder 1 Fires First: The firing sequence starts with Cylinder 1, where the spark plug ignites the air-fuel mixture.

- Cylinder 8 Fires Next: Cylinder 8 takes over, maintaining smooth power delivery.

- Cylinder 4 Engages: Cylinder 4 fires, contributing to balanced operation.

- Cylinder 3 Ignites: Cylinder 3 follows, continuing the sequence.

- Cylinder 6 Fires: Cylinder 6 ignites next, ensuring consistent operation.

- Cylinder 5 Engages: Cylinder 5 fires, maintaining rhythm in the firing cycle.

- Cylinder 7 Fires: Cylinder 7 ignites, balancing power distribution.

- Cylinder 2 Completes the Sequence: Finally, Cylinder 2 fires, and the sequence repeats.

This specific firing order ensures that power strokes are spaced evenly across the engine’s operation, optimizing performance and stability.

How the Firing Order Works in the Mopar 360

The Mopar 360 engine operates on a four-stroke cycle, which includes the following stages:

- Intake Stroke: The air-fuel mixture enters the cylinder as the intake valve opens.

- Compression Stroke: The piston compresses the mixture, preparing it for ignition.

- Power Stroke: The spark plug ignites the mixture, driving the piston downward to generate power.

- Exhaust Stroke: The exhaust valve opens, expelling the spent gases.

The firing order synchronizes these strokes across all eight cylinders, ensuring that the engine runs smoothly and delivers consistent power. The 1-8-4-3-6-5-7-2 sequence is specifically designed to balance the workload and prevent unnecessary strain on engine components.

Components Supporting the Firing Order

Several components work together to ensure the Mopar 360’s firing order is executed correctly. These include:

- Crankshaft: Converts the pistons’ vertical motion into rotational energy and determines the sequence of power strokes.

- Camshaft: Times the opening and closing of intake and exhaust valves, aligning them with the firing order.

- Distributor: Routes electrical signals to the spark plugs in the correct sequence, ensuring proper ignition timing.

- Spark Plugs: Ignite the air-fuel mixture in each cylinder at the precise moment.

- Timing Chain/Belt: Synchronizes the crankshaft and camshaft to maintain the firing order.

When these components function properly, the engine operates smoothly and efficiently.

Symptoms of Firing Order Problems

If the firing order is disrupted, the engine will exhibit noticeable symptoms. Common issues include:

- Engine Misfires: Cylinders fail to ignite properly, causing uneven power delivery.

- Rough Idling: The engine may vibrate excessively or run inconsistently at idle.

- Loss of Power: An incorrect firing order reduces efficiency, leading to sluggish acceleration.

- Backfiring: Faulty timing may cause combustion gases to ignite in the intake or exhaust system.

- Excessive Vibrations: An imbalanced firing sequence creates noticeable engine vibrations.

These issues can worsen over time, potentially causing significant engine damage if not addressed.

How to Verify the Firing Order

To ensure the Mopar 360 maintains its correct firing order, follow these steps:

- Check Spark Plug Wires: Verify that each wire is connected to the correct cylinder and distributor terminal based on the firing order.

- Inspect the Distributor Cap: Ensure the cap is properly aligned and free from damage.

- Use a Timing Light: A timing light can confirm that each spark plug fires at the appropriate moment.

- Consult the Service Manual: The correct wiring diagram and firing sequence are in the Mopar 360 service manual.

- Listen for Irregular Sounds: Sputtering, knocking, or other unusual engine noises may indicate firing order problems.

Regular checks help maintain the firing order and keep the engine running reliably.

Maintaining the Firing Order

Routine maintenance is essential to preserve the Mopar 360’s firing order and ensure optimal engine performance. Here are some tips:

- Replace Spark Plugs: Worn or fouled spark plugs can cause misfires and disrupt the firing sequence.

- Inspect Ignition Components: Check the distributor, ignition coil, and spark plug wires for wear or damage.

- Monitor the Timing Chain/Belt: Ensure the timing mechanism is properly tensioned and aligned to avoid disruptions.

- Perform Regular Tune-Ups: Routine inspections and adjustments help identify and address firing order issues early.

- Use High-Quality Fuel: Clean-burning fuel reduces carbon deposits, promoting efficient combustion.

By following these practices, you can maintain your engine’s reliability and longevity.

Can You Modify the Firing Order?

The Mopar 360’s firing order, 1-8-4-3-6-5-7-2, is specifically designed for the engine’s V8 configuration. Modifying this sequence is not recommended because:

- Imbalance Issues: Altering the firing order can cause excessive vibrations and instability.

- Reduced Efficiency: Incorrect firing disrupts combustion, leading to power loss and increased fuel consumption.

- Potential Damage: Changes to the firing order may stress internal components, causing long-term damage.

If you’re seeking performance improvements, consider upgrades like tuning the ignition system, optimizing the intake and exhaust, or improving carburetor calibration, rather than altering the firing order.

Conclusion

The Mopar 360’s firing order, 1-8-4-3-6-5-7-2, is a vital aspect of its V8 engine design. This precise sequence ensures balanced operation, smooth power delivery, and efficient combustion. Understanding and maintaining the firing order is crucial for keeping the engine running reliably and performing at its best.

By conducting regular maintenance, verifying the firing order, and addressing any issues promptly, you can preserve the performance and longevity of your Mopar 360 engine. Whether you’re restoring a classic muscle car or maintaining a daily driver, following the correct firing order ensures you’ll enjoy the power and dependability that make this engine a favorite among enthusiasts.