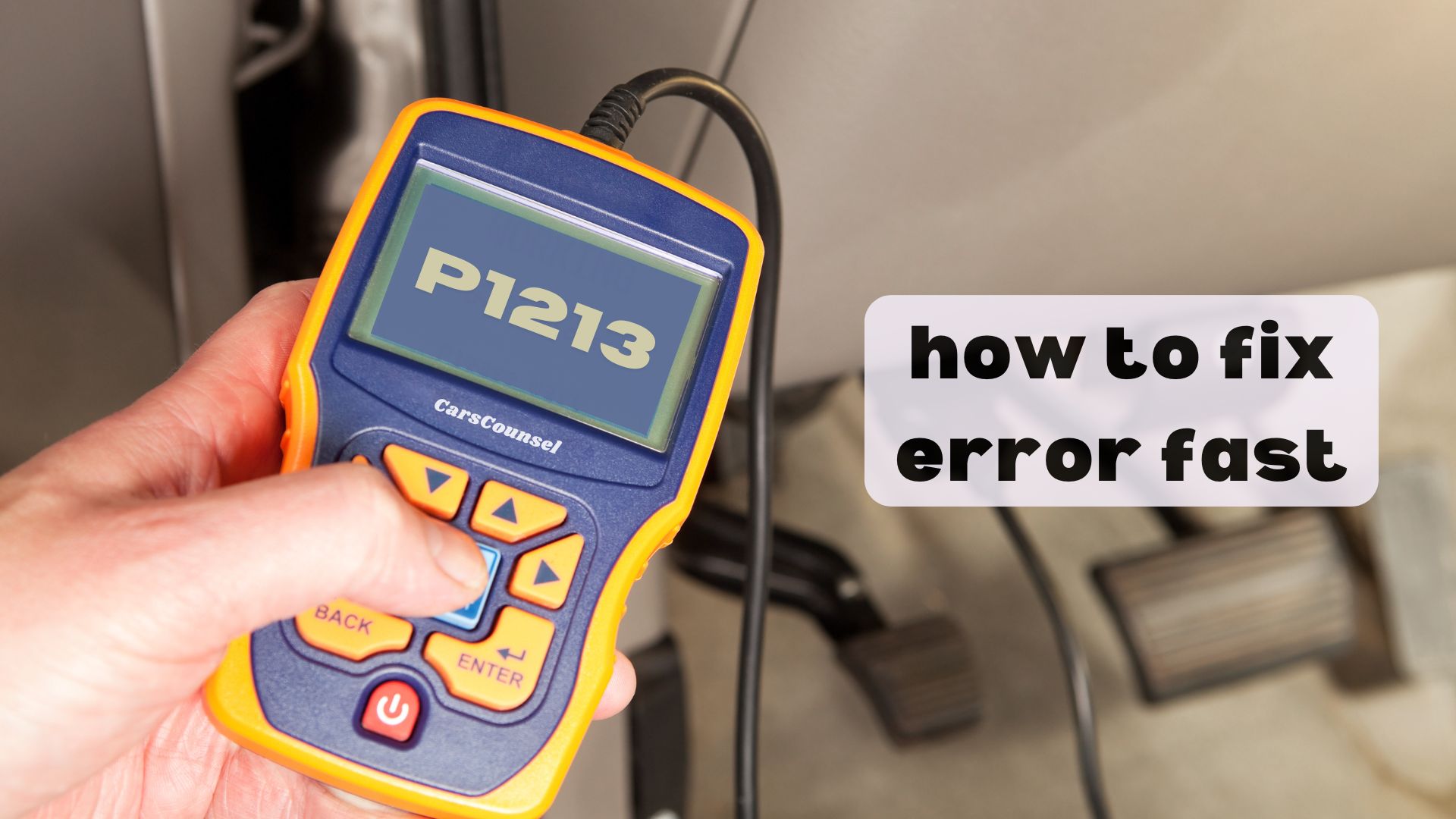

You’ve got a P1213 code staring back at you, indicating a short circuit in the injector circuit of cylinder 1, connected to positive voltage. This means your engine’s performance is likely suffering, with potential misfires, poor fuel efficiency, and rough idling.

But what’s causing this malfunction? Is it a faulty fuel injector or a wiring issue? The engine control module has detected an abnormal voltage reading, but you’ll need to dig deeper to pinpoint the root of the problem. Now, it’s time to get to the bottom of this short circuit and find a solution to get your engine running smoothly again.

Quick Navigation

Key Takeaways

- The P1213 code indicates a short circuit in the injector circuit of cylinder 1, which is connected to positive voltage. This short circuit causes poor engine performance and misfires.

- Faulty or damaged fuel injector, corrosion or wear on the injector circuit wiring or connectors, or electrical surge can cause the short circuit.

- Diagnosis involves visual inspection, voltage and resistance checks, and testing for shorts or electrical surges in the circuit using a multimeter.

- Repairing or replacing damaged components, such as the fuel injector or wiring, and ensuring proper grounding and routing of the wiring harness is necessary.

- Clearing the trouble code and testing the vehicle after repair is essential to confirm the issue is resolved and the check engine light is no longer illuminated.

Code P1213 Description and Meaning

When your vehicle’s onboard computer triggers the P1213 code, it indicates a specific problem that requires attention.

This fault code signals a short circuit in the injector circuit of cylinder 1, which is connected to positive voltage. Fundamentally, it means there’s a fault in the electrical circuit that controls the fuel injector for cylinder 1.

Injector failure or circuit malfunction could be the root cause of this issue. If left unaddressed, it can lead to poor engine performance, reduced fuel efficiency, and potential misfires.

It’s vital to diagnose and fix the problem promptly to prevent further engine damage and costly repairs.

Common Causes of the Error

Frequently, the P1213 code is triggered by a faulty injector, which is typically the primary culprit behind this error.

When the injector circuit in cylinder 1 shorts to a positive voltage, it can cause cylinder issues and disrupt the engine’s performance.

Other common causes of the P1213 code besides a faulty injector include short circuits in the wiring harness, corrosion or damage to connectors, ECM malfunction, and poor electrical connections.

These electrical faults can lead to a range of problems, including misfires, reduced fuel efficiency, and poor engine performance.

Identifying the root cause of the error is vital to fixing the issue and preventing further engine damage.

Symptoms of a Faulty Injector

Typically, a faulty injector will manifest itself through several distinct symptoms that can help you identify the problem.

You’ll likely notice issues with your engine’s performance, fuel efficiency, and overall operation.

Here are some common symptoms of a faulty injector:

- Rough Idling: Your engine may stumble or hesitate when idling, indicating poor fuel atomization.

- Fuel Leaks: You may notice fuel dripping from the injector or its connections, leading to poor engine performance and potential fire hazards.

- Injector Failure: A faulty injector can lead to engine misfires, decreased power, and poor fuel economy.

- Engine Misfires: Your engine may stumble or hesitate when accelerating, indicating a faulty injector isn’t providing the proper fuel mixture.

If you’re experiencing any of these symptoms, it’s essential to address the issue promptly to prevent further engine damage and costly repairs.

Diagnosing the Short Circuit Issue

Pinpoint the source of the short circuit by using a scan tool to retrieve trouble codes and freeze frame data, which will help you identify the cylinder and circuit affected. Next, perform a circuit analysis to determine if the short circuit is on the positive or negative side of the injector circuit.

| Step | Action | Purpose |

|---|---|---|

| 1 | Connect a multimeter to the injector circuit | Measure voltage and resistance to identify the short circuit |

| 2 | Perform voltage checks on the injector circuit | Determine if the voltage is within the specified range |

| 3 | Use a wiring diagram to trace the injector circuit | Identify the location of the short circuit |

| 4 | Check for corrosion or damage on the connectors and wiring | Identify any signs of wear or damage that may be causing the short circuit |

Inspecting the Wiring Harness

Inspecting the wiring harness is a crucial step in identifying the source of the short circuit.

You’ll want to carefully examine the wiring and connectors for any signs of damage, corrosion, or wear.

This is where wiring faults can often be found.

- Check for frayed or damaged wires, which can cause short circuits.

- Inspect connectors and terminals for corrosion or damage.

- Look for signs of overheating, such as melted insulation or burn marks.

- Verify proper routing and securing of the wiring harness to prevent chafing or pinching.

Testing the Injector Circuit

One faulty injector circuit can cause the entire engine to malfunction, making it essential to test the injector circuit thoroughly. You’ll need to perform a circuit analysis to identify the source of the short circuit. Start by checking the voltage at the injector connector using a multimeter. Compare your readings to the manufacturer’s specifications to verify the voltage is within range.

| Test Point | Expected Voltage Reading | Notes |

|---|---|---|

| Injector Connector | 10-12V | Check for signs of corrosion or damage |

| Wiring Harness | 0V | Verify no voltage present when ignition is off |

| ECM Connector | 5-10V | Check for proper communication between ECM and injector |

| Ground Connection | 0V | Certify proper grounding to prevent voltage leaks |

Repairing or Replacing Damaged Components

When you’ve identified the faulty component in the injector circuit, it’s time to take corrective action.

You’ve completed the circuit troubleshooting and pinpointed the issue. Now, it’s essential to repair or replace the damaged components to prevent further engine damage.

- Replace the faulty fuel injector: If the injector is damaged, replace it with a new one to guarantee proper fuel flow and pressure.

- Repair or replace damaged wiring: Inspect the wiring harness and connectors for corrosion or damage. Repair or replace them as needed to certify a secure connection.

- Clean or replace corroded connectors: Corrosion can cause a short circuit. Clean or replace corroded connectors to guarantee a reliable connection.

- Check the ECM for malfunction: If the ECM is faulty, it may need to be replaced or reprogrammed to resolve the issue.

Clearing Trouble Codes and Testing

After repairing or replacing the damaged components, you’re ready to clear the trouble codes and test the system to verify the issue is resolved.

Use a scan tool to connect to your vehicle’s onboard computer and access the trouble code menu. Select the “code reset” option to clear the P1213 code. Follow the scan tool’s instructions to complete the code reset process.

Once cleared, test drive your vehicle to confirm the issue is resolved and the check engine light is no longer illuminated. If the code returns, it may indicate that the repair wasn’t successful, and further diagnosis is required.

Remember to always follow proper code reset methods to avoid causing additional problems with your vehicle’s computer system.

Average Repair Cost and Labor Rates

The cost of repairing a P1213 code can vary significantly depending on the underlying cause and the labor rates of your local auto repair shop.

You’ll want to get a detailed estimate from a trusted mechanic before proceeding with repairs.

Here are some factors that can affect the average repair cost:

- Shop Estimators: Labor rates at auto repair shops can vary widely, so it’s essential to get quotes from multiple shops to compare prices.

- Repair Timelines: The time it takes to diagnose and repair the issue can impact the overall cost, so be sure to ask about the estimated repair time.

- Parts and Materials: The cost of replacement parts, such as a new injector or wiring harness, can add up quickly.

- Diagnostic Fees: Some shops may charge a diagnostic fee to pinpoint the cause of the short circuit, which can add to the overall cost.

On average, the repair cost ranges from $150 to $500, including parts and labor.

Additional Resources and Next Steps

Your mechanic’s diagnosis of a P1213 code has left you wondering what’s next.

You’re likely looking for additional resources and guidance to guarantee you’re on the right track. If you’re not comfortable with DIY repairs, consider seeking professional guidance from a trusted mechanic.

They can provide additional assistance in diagnosing and fixing the issue. You can also consult factory service manuals for more information on the P1213 code and its repair.

In addition, online forums and repair communities can offer valuable insights from others who’ve experienced similar issues. Don’t hesitate to ask for help – getting it right the first time will save you time and money in the long run.

More OBD-II Codes

Frequently Asked Questions

Can I Continue Driving With a P1213 Code?

You should exercise driving precautions with a P1213 code, as it can lead to poor fuel efficiency, misfires, and further engine damage. It’s recommended to address the issue promptly to avoid more costly repairs and potential safety risks.

Will a P1213 Code Cause My Engine to Seize?

You’re wondering if a P1213 code will cause your engine to seize. Fortunately, it’s unlikely to happen immediately, but prolonged driving with a short circuit can lead to fuel pressure issues, affecting engine performance, which may eventually cause engine damage or seizure if left unaddressed.

Can I Repair a P1213 Code Myself?

Don’t worry, you’re not stuck with a hefty repair bill! If you’re comfortable with basic electrical diagnosis, you can try fixing a P1213 code yourself by inspecting the fuel injector and circuit wiring for shorts or corrosion, and making repairs accordingly.

Will a Tune-Up Fix a P1213 Code?

When you’re wondering if a tune-up will fix the issue, the answer is no, as a tune-up typically includes spark plug replacement and fuel injector cleaning, which won’t address the short circuit in the injector circuit that’s causing the problem.

Can a Faulty Oxygen Sensor Cause a P1213 Code?

You’ve got a faulty oxygen sensor, but will it trigger a P1213 code? Let’s consider a scenario: if the oxygen sensor malfunctions, it can alter the oxygen signal, but it’s unlikely to cause a short circuit in the injector circuit, so it won’t directly trigger a P1213 code.

Conclusion

You’ve finally pinpointed the culprit behind your engine’s sluggish performance – the P1213 code. But don’t think you’re out of the woods yet. As you plunge further into the injector circuit, you’ll need to navigate a maze of wires and components, where one wrong move can spark a fire or blow a fuse. Will you emerge victorious, with a purring engine and a sense of triumph? Or will the code continue to haunt you, a constant reminder of the battle ahead?