The VQ35DE engine is a popular V6 engine known for its reliability and performance. Understanding its firing order is essential for maintenance, troubleshooting, and performance tuning. This guide explains the firing order, its significance, and related considerations in a clear, concise format.

Quick Navigation

VQ35DE Firing Order

- Cylinder 1 fires first.

- Cylinder 2 fires second.

- Cylinder 3 fires third.

- Cylinder 4 fires fourth.

- Cylinder 5 fires fifth.

- Cylinder 6 fires sixth.

The sequence repeats as the engine cycles.

What is the Firing Order?

The firing order determines the sequence in which the engine’s cylinders fire during operation. The VQ35DE, a six-cylinder engine, uses a specific firing order to ensure smooth power delivery and balance.

Why the Firing Order Matters

- Engine Balance: The correct firing order minimizes vibrations and ensures even power delivery.

- Fuel Efficiency: Proper sequencing enhances combustion efficiency and reduces wasted energy.

- Smooth Operation: The correct order prevents misfires and contributes to a steady engine rhythm.

- Component Longevity: Reduced stress on internal components increases the lifespan of the engine.

How the Firing Order Works in the VQ35DE

The VQ35DE engine is a 60-degree V6 engine. Each cylinder fires in a specific sequence to maintain balance. The arrangement uses the even spacing of the crankshaft’s rotation to ensure each cylinder contributes proportionally to engine power.

- The crankshaft rotates 720 degrees for a full cycle.

- Each cylinder fires once during these 720 degrees.

- The cylinders alternate between banks to maintain smooth operation.

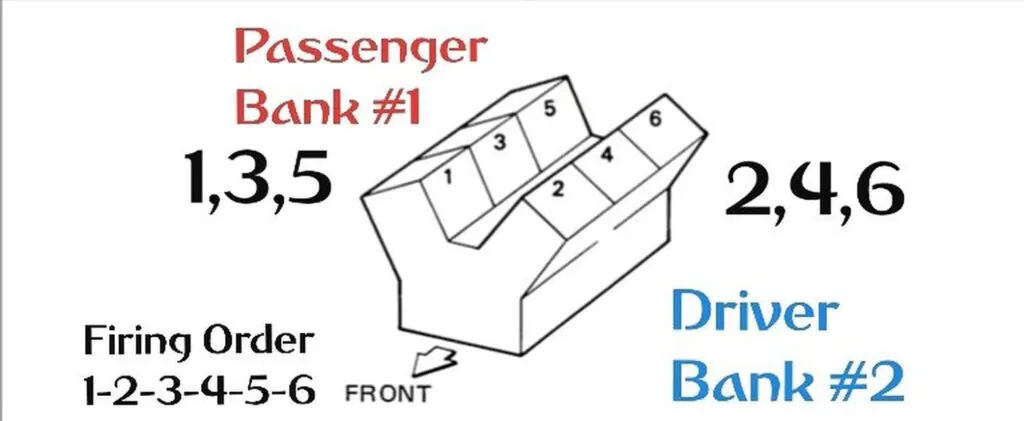

Cylinder Numbering in the VQ35DE

Correctly identifying cylinders is crucial for understanding the firing order. In the VQ35DE:

- Bank 1 contains cylinders 1, 3, and 5.

- Bank 2 contains cylinders 2, 4, and 6.

The cylinder numbering follows:

- Bank 1: Front of engine, 1-3-5 (left side in longitudinal layouts).

- Bank 2: Front of engine, 2-4-6 (right side in longitudinal layouts).

This numbering system helps diagnose issues or replace components.

Key Components Involved in Firing

Several components work together to execute the firing order in the VQ35DE:

- Crankshaft: Converts linear piston motion into rotational energy.

- Camshafts: Control valve timing to synchronize combustion.

- Ignition Coils: Deliver high-voltage sparks to the spark plugs.

- Spark Plugs: Ignite the air-fuel mixture in each cylinder.

- ECU (Engine Control Unit): Orchestrates timing for ignition and fuel injection.

Each component must function correctly for the firing order to work efficiently.

Common Issues Related to Firing Order

Misfires: A disrupted firing order can cause uneven combustion.

- Symptoms: Rough idling, reduced power, increased emissions.

- Causes: Faulty ignition coils, worn spark plugs, or timing issues.

Vibrations: Incorrect firing order may lead to excessive engine vibrations.

- Diagnosis: Check cylinder balance and crankshaft alignment.

Engine Knock: A misaligned firing order may lead to pre-ignition or detonation.

- Prevention: Use proper timing and high-quality fuel.

Loss of Power: Incorrect firing disrupts power delivery and efficiency.

How to Check the Firing Order

- Refer to the Manual: Confirm the manufacturer’s specifications.

- Inspect the ignition system: Ensure proper spark plug and ignition coil connections are made.

- Use Diagnostic Tools: Utilize an OBD-II scanner for error codes.

- Test Cylinder Functionality: Perform a cylinder balance test to verify the firing sequence.

Adjusting the Firing Order

The firing order in the VQ35DE cannot be altered without modifying the engine’s physical design. However, tuning involves ensuring:

- Correct Timing: Adjust the camshaft and crankshaft timing.

- Proper Spark Delivery: Test and replace ignition components as needed.

- Injector Calibration: Maintain synchronized fuel delivery.

These adjustments ensure the engine operates within factory specifications.

Importance of Timing in the VQ35DE

The VQ35DE engine uses a timing chain system for durability and precision. Proper timing ensures:

- Cylinders fire at the correct intervals.

- Valves open and close in sync with the crankshaft.

- Combustion occurs efficiently within each cylinder.

If the timing chain stretches or skips, the firing order can be affected.

Troubleshooting Firing Order Issues

- Listen for Unusual Noises: Knocking or pinging may indicate firing order issues.

- Check Engine Light: Misfires trigger diagnostic trouble codes (DTCs).

- Inspect Timing Chain: A loose or worn chain disrupts timing.

- Test Spark Plugs and Coils: Replace any faulty components.

- Verify Fuel Delivery: Ensure injectors provide consistent fuel flow.

Maintenance Tips for Optimal Firing

- Replace Spark Plugs Regularly: Worn plugs reduce combustion efficiency.

- Inspect Ignition Coils: Faulty coils can disrupt spark delivery.

- Maintain Timing Chain: Replace the chain as per manufacturer recommendations.

- Use Quality Fuel: Prevents deposits that can interfere with combustion.

- Keep Sensors Clean: Ensure accurate inputs for the ECU.

Performance Tuning and the Firing Order

Enthusiasts often tune the VQ35DE for increased performance. The firing order plays a role in optimizing:

- Power Output: Ensures all cylinders contribute effectively.

- Turbocharging or Supercharging: Maintains balance under increased loads.

- Aftermarket Ignition Systems: Enhances spark efficiency.

When tuning, always adhere to the factory firing order to avoid engine damage.

Engines with Similar Firing Orders

- Datsun 240z Firing Order

- Datsun 260Z Firing Order

- Xterra Firing Order

- Nissan V6 Firing Order

- 2006 Nissan Altima Firing Order

Final Thoughts

The VQ35DE firing order (1-2-3-4-5-6) is a critical aspect of this engine’s design. Proper understanding ensures smooth operation, efficient combustion, and prolonged engine life. By maintaining the ignition and timing systems, you can prevent issues and optimize performance. Whether for routine maintenance or advanced tuning, always prioritize the integrity of the firing sequence.