Forklifts are essential tools for material handling, and Yale forklifts are known for their reliability and efficiency. The performance of these machines depends heavily on their engines, and an essential aspect of engine functionality is the firing order.

Understanding the firing order of a Yale forklift engine can help operators and mechanics maintain optimal performance and address issues when they arise.

In this guide, we’ll explore everything you need to know about the firing order of Yale forklift engines, why it matters, and how to troubleshoot and verify the firing order effectively.

Quick Navigation

What Is a Firing Order?

The firing order refers to the specific sequence in which an engine’s spark plugs ignite the air-fuel mixture within the cylinders. This ignition creates the controlled explosions that power the engine.

The firing order is predetermined by the engine’s design and is crucial for smooth and efficient operation.

Why Does the Firing Order Matter?

- Smooth Operation: Proper firing ensures minimal vibration and consistent engine operation.

- Efficiency: A correct sequence optimizes fuel combustion, improving energy efficiency.

- Balanced Load: Even power distribution minimizes wear on engine components.

- Reliability: Ensures consistent power output, essential for heavy lifting operations.

Yale Forklift Engine Types

Yale forklifts use a variety of engines, depending on the model and fuel type. These engines may be powered by:

- Internal Combustion Gasoline or LPG: Inline-4 or V6 configurations.

- Diesel: Inline-4 or V6 engines.

- Electric Motors: While not relevant to firing order discussions, electric forklifts are an alternative.

For this article, we’ll focus on internal combustion engines, specifically the popular inline-4 and V6 engines found in many Yale forklift models.

Engine Configurations in Yale Forklifts

- Inline-4 Engines: Four cylinders arranged in a single line.

- V6 Engines: Six cylinders arranged in a “V” shape with two banks of three cylinders.

Cylinder Numbering

- Inline-4 Engines: Cylinders are numbered sequentially from front to back, i.e., 1-2-3-4.

- V6 Engines: Cylinders are divided into two banks:

- Bank 1: Cylinders 1, 3, 5

- Bank 2: Cylinders 2, 4, 6

Common Firing Orders for Yale Forklifts

The firing order depends on the engine configuration, and knowing the correct sequence is crucial for maintaining optimal performance.

Inline-4 Engines

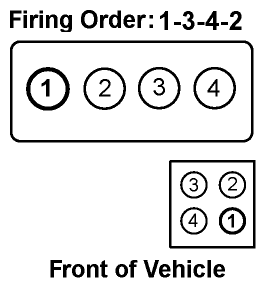

The most common firing order for Yale forklifts with inline-4 engines is: 1-3-4-2

- Cylinder 1 fires first, followed by cylinder 3, then cylinder 4, and finally cylinder 2.

- This order balances the engine by alternating between the cylinders in a way that minimizes vibration.

V6 Engines

For Yale forklifts equipped with V6 engines, the firing order is typically: 1-4-2-5-3-6

- This sequence alternates between the two cylinder banks, ensuring even power distribution and smooth operation.

How to Identify the Firing Order on a Yale Forklift

Consult the Owner’s Manual

The most reliable source of information is the owner’s manual or engine service manual provided by Yale or the engine manufacturer. These manuals include diagrams and firing order specifications.

Inspect the Engine Block

Engraved cylinder numbers on the engine block or near the spark plugs can help you identify the firing order.

Use Diagnostic Tools

Professional diagnostic tools can verify ignition timing and confirm whether the firing sequence matches the manufacturer’s specifications.

The Role of Firing Order in Engine Performance

The firing order is more than just a technical specification—it directly impacts the forklift’s functionality. Here’s how:

Power Delivery

- Proper firing ensures consistent power output, which is critical for lifting heavy loads without stalling or struggling.

Fuel Efficiency

- A correct firing order optimizes combustion, reducing fuel consumption and emissions.

Vibration Reduction

- Balanced cylinder firing minimizes engine vibrations, extending component life and improving operator comfort.

Maintenance Costs

- Maintaining the correct firing sequence prevents misfires, reducing the likelihood of costly repairs.

Troubleshooting Firing Order Problems

Incorrect firing order can cause a range of issues, affecting the forklift’s performance and reliability. Here’s what to look for and how to fix it.

Symptoms of Incorrect Firing Order

- Engine Misfires: Cylinders fail to ignite at the right time, leading to erratic performance.

- Loss of Power: The forklift struggles to lift loads or accelerates slowly.

- Rough Idling: The engine vibrates excessively or feels unstable when idle.

- Excessive Fuel Consumption: Inefficient combustion leads to higher fuel usage.

- Unusual Noises: Irregular firing can create knocking or pinging sounds.

Diagnostic Steps

- Check Spark Plug Wiring: Ensure each wire connects the correct spark plug to the appropriate ignition coil.

- Inspect Timing Components: Verify that the timing belt or chain is aligned with the engine’s firing order.

- Scan for Error Codes: Use an OBD-II scanner to identify misfire codes or timing-related errors.

- Verify Ignition Timing: Use a timing light to ensure the spark plugs fire at the correct intervals.

Preventative Maintenance

Proper maintenance can prevent firing order issues and ensure your Yale forklift performs reliably.

Regular Inspections

- Inspect spark plugs, ignition wires, and timing belts/chains for wear or damage.

- Ensure proper connections and alignment during routine checks.

Timely Component Replacement

- Replace spark plugs, ignition coils, and related components at recommended intervals.

- Use OEM parts to guarantee compatibility and performance.

Follow Manufacturer Guidelines

- Always adhere to Yale’s service schedules and recommendations for engine maintenance.

Adjusting or Verifying the Firing Order

While the firing order cannot be changed, verifying that it is correctly implemented is essential. Here’s a step-by-step guide:

- Disconnect Power: For safety, disconnect the forklift’s battery.

- Locate Cylinder Numbers: Identify cylinder numbers on the engine block.

- Trace Ignition Wires: Follow each spark plug wire to ensure it connects to the correct cylinder based on the firing order.

- Confirm Timing Alignment: Check the timing belt/chain alignment with the crankshaft and camshaft.

- Reassemble and Test: Reconnect the battery, start the engine, and listen for smooth operation.

FAQs About Yale Forklift Firing Order

Can I Change the Firing Order?

No, the firing order is determined by the engine’s design and crankshaft configuration. Modifying it would require extensive engine redesign.

What Happens If the Firing Order Is Wrong?

An incorrect firing order causes misfires, loss of power, and potential damage to the engine.

Is the Firing Order the Same for All Yale Forklift Models?

No, the firing order varies depending on the engine type and configuration.

How Do I Verify the Firing Order?

Follow the ignition wires and confirm they match the manufacturer’s specifications. Diagnostic tools can also verify the ignition timing.

Conclusion

Understanding the firing order of a Yale forklift engine is essential for maintaining its performance, efficiency, and reliability. Whether your forklift uses an inline-4 or a V6 engine, knowing the correct sequence—1-3-4-2 for inline-4 and 1-4-2-5-3-6 for V6—can help you troubleshoot issues and keep the machine running smoothly.

By staying proactive with maintenance, verifying ignition components, and adhering to manufacturer guidelines, you can ensure your Yale forklift delivers consistent performance and handles the toughest jobs with ease.