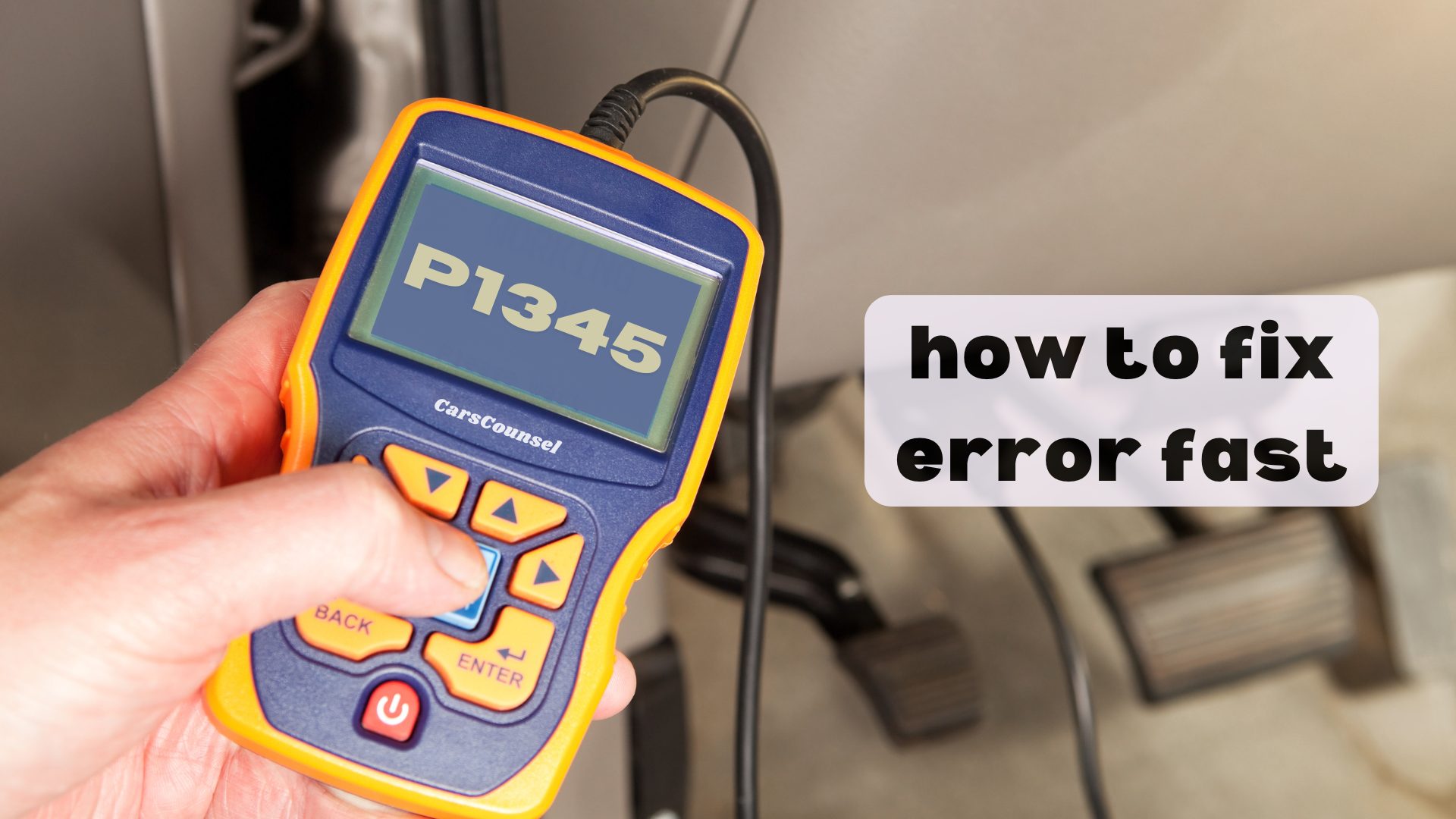

You’re faced with the P1345 code, which means your engine’s crankshaft and camshaft positions are out of sync. This misalignment can lead to frustrating issues like misfires, rough idling, and difficulty starting the engine. But what’s causing this correlation problem?

Is it a faulty sensor, worn-out chain, or perhaps a wiring issue? Getting to the root of the problem is vital to restoring your engine’s performance and fuel efficiency. As you start to investigate, you’ll likely uncover more questions than answers – and that’s exactly where your journey to resolving the P1345 error code begins.

Quick Navigation

Key Takeaways

- P1345 code indicates a correlation issue between the crankshaft and camshaft position sensors, affecting engine timing and performance.

- Faulty sensors, chain wear, or wiring issues can cause misalignment, leading to engine misfires, rough idle, and difficulty starting the engine.

- Diagnosing the issue involves using a scan tool, inspecting sensors and wiring, and verifying timing chain or belt alignment.

- Repairing the issue may involve replacing faulty sensors, addressing wiring or connection issues, or adjusting the timing chain or belt.

- Proper engine timing is crucial for peak performance, fuel efficiency, and engine longevity, making prompt resolution of the P1345 code essential.

Understanding Code P1345

When your vehicle’s onboard computer throws a P1345 code, it’s signaling a problem with the correlation between the crankshaft position sensor and the camshaft position sensor.

These sensors verify proper engine timing, which is essential for the engine to run smoothly and efficiently. Sensor accuracy is vital, as any misalignment can lead to performance issues.

If these sensors aren’t in sync, you may experience engine misfires, rough idle, or difficulty starting the engine. To maintain peak engine performance, it’s essential to address this issue promptly.

Causes of Crankshaft-Camshaft Misalignment

A misalignment between the crankshaft and camshaft position sensors can occur due to various reasons.

You might be dealing with a faulty crankshaft or camshaft position sensor, which can cause the sensors to malfunction and lose sync. Sensor failure can be caused by wear and tear, corrosion, or physical damage.

Additionally, chain wear can also contribute to misalignment, as a worn-out timing chain can cause the crankshaft and camshaft to lose their precise correlation.

Wiring or connection issues between the sensors and the Engine Control Module (ECM) can also disrupt the signal, leading to misalignment.

Identifying the root cause of the misalignment is vital to resolving the P1345 code and restoring proper engine timing.

Symptoms of P1345 Code

Engine performance issues can manifest in various ways, and the P1345 code is no exception. You may notice that your engine is misfiring, idling rough, or having difficulty starting. These symptoms can be frustrating and affect your vehicle’s overall performance.

| Symptoms | Description | Impact on Vehicle |

|---|---|---|

| Engine Misfires | Irregular combustion in the engine | Reduced power and efficiency |

| Rough Idle | Unstable engine operation at low RPM | Faulty Engine performance |

| Difficulty Starting | Engine struggles to turn over | Delays and inconvenience |

| Reduced Fuel Efficiency | Decreased miles per gallon | Increased fuel costs |

These symptoms can be indicative of a faulty engine, and it’s essential to address them promptly to prevent further damage. Rough performance can lead to more severe issues if left unchecked.

Diagnosing the Correlation Issue

Diagnosing the correlation issue between the crankshaft and camshaft position sensors requires a methodical approach to pinpoint the root cause of the P1345 code.

You’ll need to use sensor inspection and troubleshooting techniques to identify the problem. Start by using a scan tool to read the DTC and check the sensor data.

Then, inspect the crankshaft and camshaft position sensors for any signs of damage or malfunction. Check the wiring harness and connections for breaks, corrosion, or loose connections.

Verify the timing chain or belt alignment and adjust if necessary. By following these steps, you’ll be able to identify the root cause of the issue and take the necessary steps to repair it.

Repairing P1345 Code Issues

Several faulty components can trigger the P1345 code, and repairing the issue requires a thorough understanding of the underlying causes.

You’ll need to identify the root cause of the problem, whether it’s a faulty crankshaft position sensor, camshaft position sensor, or wiring issues. Once you’ve diagnosed the issue, you can begin repairs.

Sensor replacement may be necessary, which can improve engine performance. Make sure to inspect the wiring harness and connections, and verify the timing chain or belt alignment.

After making repairs, clear the DTC and perform a road test to confirm the issue has been resolved. By following these steps, you can restore proper engine timing and get your vehicle running smoothly again.

Cost of Repair and Replacement

Your vehicle’s repair bill for a P1345 code issue will depend on the faulty component and the labor costs of your chosen mechanic or auto repair shop.

Replacing a faulty sensor can cost between $50 to $200, while addressing wiring or connection issues may range from $100 to $300. Adjusting the timing chain or belt can cost between $300 to $800.

Labor costs can add an additional $80 to $150 per hour, depending on the shop rates. To get a more accurate repair estimate, consult with a qualified mechanic or auto repair shop, as the cost can vary depending on your vehicle’s make and model.

Be sure to ask about their shop rates and get a detailed breakdown of the repair costs to plan your budget accordingly.

Preventing Future Correlation Problems

Regular maintenance and inspections can help prevent future correlation problems between the crankshaft and camshaft position sensors, ensuring your engine runs smoothly and efficiently.

By prioritizing sensor maintenance, you can identify potential issues before they cause problems. Regular inspections of the sensors, wiring, and connections can help you catch signs of wear or damage early on.

This proactive approach can save you time and money in the long run. Additionally, keeping your engine well-maintained through regular oil changes, tune-ups, and other necessary repairs can also help prevent correlation problems.

Importance of Proper Engine Timing

As the engine’s rhythmic pulse relies on precise synchronization between the crankshaft and camshaft, proper engine timing is crucial for peak performance and fuel efficiency. You’ll experience significant benefits when your engine is in harmony.

| Timing Benefits | Description |

|---|---|

| Improved Fuel Efficiency | Ideal engine timing guarantees the perfect air-fuel mixture, reducing fuel consumption and emissions. |

| Amplified Performance | Proper synchronization enables the engine to produce more power and torque, resulting in a smoother ride. |

| Reduced Engine Wear | Well-timed engine components reduce friction and wear, extending the engine’s lifespan.

More OBD-II Codes

Frequently Asked Questions

Can a Dirty Crankshaft Position Sensor Cause a P1345 Code?

You’re wondering if a dirty crankshaft position sensor can trigger a P1345 code. Yes, it can, as dirt and grime can cause sensor malfunction, leading to correlation issues between the crankshaft and camshaft sensors.

Will a P1345 Code Trigger the Check Engine Light Immediately?

You’ll likely see the check engine light illuminate immediately if the P1345 code is triggered, especially if the sensor malfunction is severe, as it directly affects engine performance and timing, making it a critical issue that requires prompt attention.

Can I Drive My Car With a P1345 Code Safely?

You can drive your car with a P1345 code, but it’s not recommended as it may lead to reduced fuel efficiency and compromise safe acceleration, potentially causing further engine damage or stalling, especially during heavy loads or high-speed driving.

Will a Tune-Up Fix a P1345 Code Issue?

As you spark to life your engine’s hidden issues, a tune-up might tweak timing, but it won’t fix the faulty sensor sync, spark plug wear, or ignition timing misfires that trigger the P1345 code, so dig deeper to diagnose the root cause.

Can a P1345 Code Cause Engine Damage if Left Unfixed?

If you leave the issue unfixed, you’ll risk engine wear, decreased oil pressure, and potentially catastrophic engine damage, as misfires and poor timing can cause excessive heat, scoring, and premature wear on moving parts.

Conclusion

You’ve resolved the P1345 code issue, but don’t forget that proper engine timing is vital for your vehicle’s longevity. Did you know that a misaligned crankshaft and camshaft can decrease fuel efficiency by up to 20%? By addressing this issue promptly, you’ve saved yourself from potential long-term damage and costly repairs. Remember, regular maintenance is key to maintaining your engine’s rhythmic pulse and peak performance.