You’re probably wondering what’s going on with your vehicle when the check engine light comes on, and the P1712 code appears. This code indicates a problem with the engine torque control signal 2 circuit, which can lead to decreased fuel efficiency, poor acceleration, and rough idling.

But what’s causing it? Is it a faulty sensor or damaged wiring? You’re likely anxious to find out and get your vehicle running smoothly again. Let’s take a closer look at what’s behind this code and what you can do to fix it.

Quick Navigation

Key Takeaways

- The P1712 code indicates a malfunction in the engine torque control signal 2 circuit, which can affect vehicle performance and fuel efficiency.

- Faulty components, damaged wiring, electrical surges, and corroded connections can trigger the P1712 code, which can lead to decreased fuel efficiency and poor acceleration.

- Symptoms of engine torque malfunction include decreased fuel efficiency, poor acceleration, rough idling, engine hesitation, and stalling.

- A systematic approach is necessary to diagnose the P1712 trouble code, which includes retrieving the trouble code, inspecting the engine torque control sensor and wiring, and testing the torque control module.

- Repairing the engine torque control system involves inspecting and cleaning or replacing faulty components, calibrating the new torque sensor, and performing a tune-up to fine-tune engine performance.

Code P1712 Description and Meaning

When your vehicle’s onboard computer generates the diagnostic trouble code P1712, it indicates a malfunction in the engine torque control signal two circuits.

This error code affects your vehicle’s performance, causing issues with the engine’s ability to adjust torque output efficiently. The engine torque control system manages power delivery to the wheels based on various driving conditions.

When this system malfunctions, it can lead to decreased fuel efficiency, poor acceleration, rough idling, and reduced engine performance overall. Torque sensors play a vital role in this system, and a faulty sensor can trigger the P1712 code.

The code typically affects your vehicle’s overall performance and fuel efficiency, making it essential to address the issue promptly.

Common Causes of the P1712 Code

Faulty components in the engine torque control system can trigger the P1712 code.

As you investigate the issue, you’ll want to focus on the most common causes.

Here are four potential culprits:

- Faulty wiring: Damaged or corroded wiring can disrupt the signal to the engine torque control system, leading to the P1712 code.

- Electrical surges: Sudden electrical surges can damage the system’s components, causing a malfunction.

- Faulty engine torque control sensor: A malfunctioning sensor can provide incorrect data to the engine computer, triggering the code.

- Corroded electrical connections: Corrosion in the electrical connections can prevent the system from functioning properly, resulting in the P1712 code.

Symptoms of Engine Torque Malfunction

As you investigate the P1712 code, it’s essential to recognize the symptoms that indicate engine torque malfunction.

You may notice decreased fuel efficiency, which can be frustrating and costly. Additionally, poor acceleration and rough idling can make your vehicle less responsive and unpleasant to drive.

Engine hesitation and stalling are also common symptoms of torque issues, which can be hazardous, especially when driving in heavy traffic.

The Check Engine Light will likely illuminate, alerting you to the problem.

Diagnosing the P1712 Trouble Code

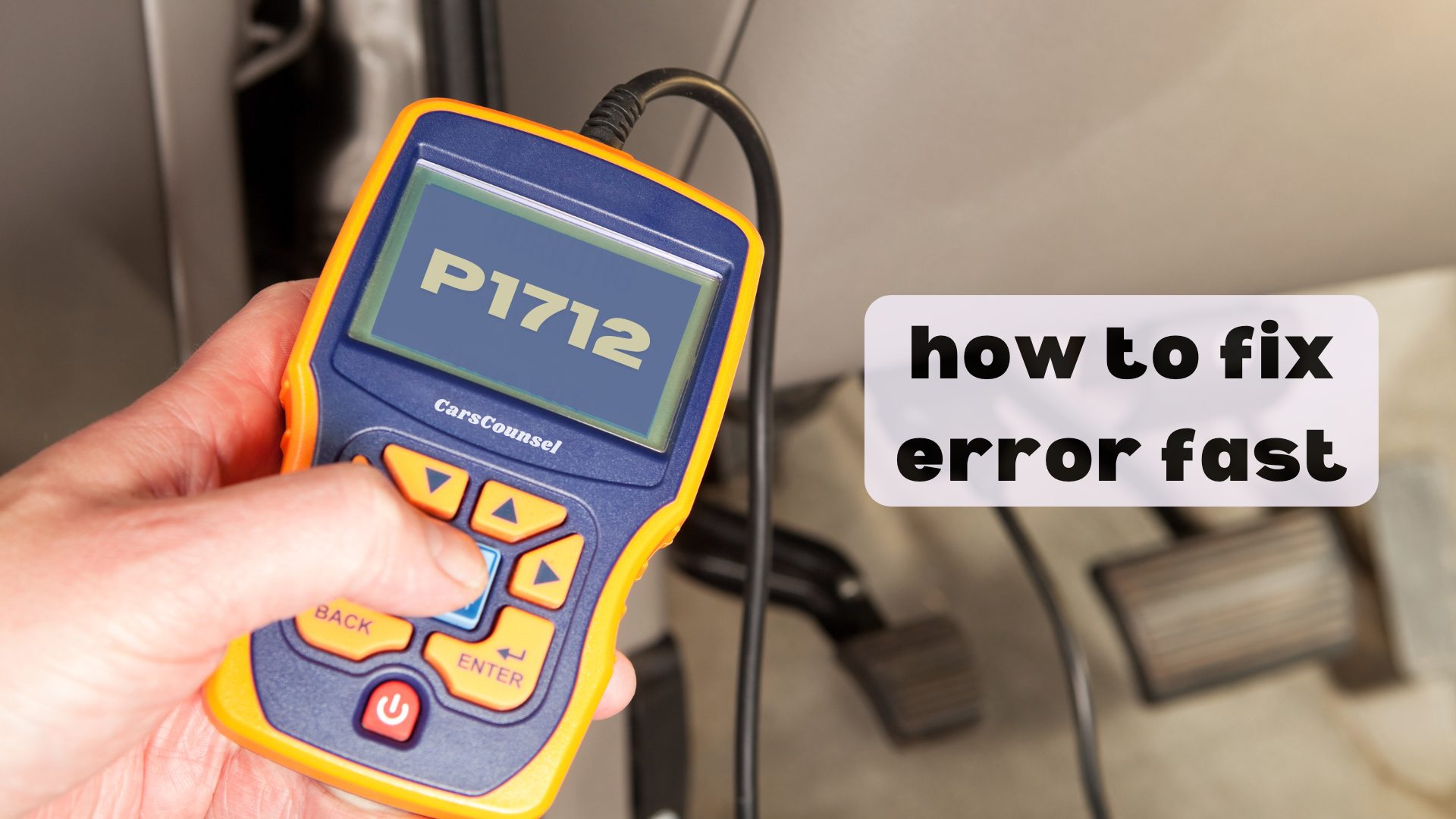

To diagnose the P1712 trouble code, you’ll need to follow a systematic approach to identify the root cause of the issue.

This code is often caused by torque fluctuations, which can be triggered by a faulty engine torque control sensor or malfunctioning torque control module.

- Begin by retrieving the trouble code using a diagnostic scanner to understand the specific issue.

- Inspect the engine torque control sensor and wiring for any visible damage or corrosion.

- Test the torque control module to determine if it’s functioning properly.

- If necessary, perform sensor recalibration to guarantee accurate torque output, and verify that the recalibration process is successful to guarantee accurate torque output.

Repairing the Engine Torque Control System

With the diagnosis complete, you’re now ready to tackle the repairs. The goal is to restore peak engine performance and fuel efficiency by repairing or replacing faulty components in the engine torque control system.

| Repair Step | Description |

|---|---|

| Inspect and clean | Inspect the engine torque control sensor and wiring for corrosion or damage. Clean any corroded connections to guarantee proper signal transmission. |

| Replace faulty components | Replace the engine torque control sensor, wiring, or torque control module if found faulty during testing. |

| Torque sensor calibration | Calibrate the new torque sensor to certify accurate signal transmission to the ECU. |

| Engine performance optimization | Perform a tune-up to fine-tune engine performance, including adjusting ignition timing and fuel injection. |

| Clear trouble code | Clear the P1712 trouble code from the ECU memory and test drive the vehicle to verify the issue is resolved.

Cost of Repair and Labor Rates

When estimating the cost of repairs for the P1712 code, you’ll need to factor in both parts and labor costs, which can vary significantly depending on the auto repair shop, location, and make of your vehicle.

The time it takes to diagnose the issue can range from 1-2 hours, depending on the complexity of the problem.

- Diagnostic time:

- Parts costs: Replacing faulty sensors, wiring, or torque control modules can add up to $200-$300.

- Labor rates: Labor costs can range from $75 to $150 per hour, depending on the shop’s rates.

- Additional repairs: If other issues are discovered during the diagnosis, additional repairs may be required, adding to the overall cost.

Remember to get a detailed quote from a trusted mechanic or repair shop before proceeding with the repairs.

Importance of Accurate Diagnosis

Accurate diagnosis is essential in addressing the P1712 code, as it directly impacts the effectiveness of the repair.

You need to pinpoint the root cause of the issue to guarantee that the correct components are replaced or repaired. If you misdiagnose the problem, you may end up replacing unnecessary parts or overlooking the actual culprit.

This can lead to additional costs, wasted time, and continued torque variations that affect your vehicle’s performance. Proper sensor calibration is pivotal in resolving the P1712 code, and accurate diagnosis is key to achieving this.

More OBD-II Codes

Conclusion

As you shift gears, your engine purrs smoothly, thanks to the precise calibration of its torque control system. But when the P1712 code strikes, it’s like a misfire in the rhythm of your engine’s performance. Don’t let it linger – diagnose and repair the issue promptly to avoid fuel efficiency woes and rough idling. With accurate diagnosis, you’ll be back on the road, cruising smoothly, and enjoying peak engine performance.