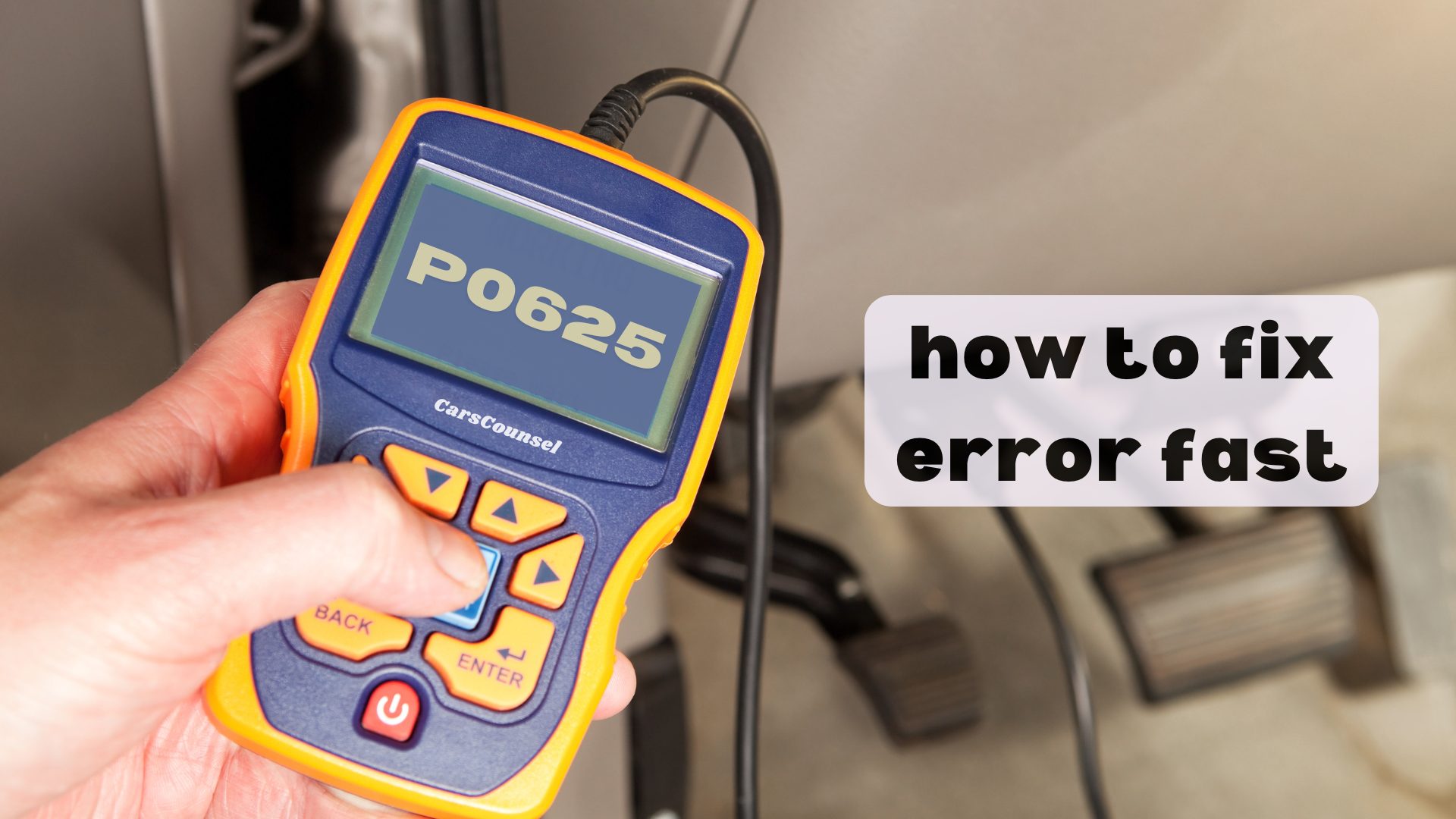

When you see the P0625 code, it’s important to act quickly to prevent bigger problems later.

Start by checking the generator field control circuit for any OBD2 issues like damaged wires or loose connections.

Use a multimeter to test the battery voltage and alternator output.

If you find that the generator is faulty, you’ll need to replace it and fix any corroded connectors.

Diagnosing the problem is just the first step; understanding why it happened and keeping up with regular maintenance can save you a lot of trouble.

So, what’s the next step to tackle this code efficiently?

Quick Navigation

Key Takeaways

- Check and replace the faulty generator to make sure it produces the right voltage.

- Look for and fix any damaged or corroded wires and connectors in the generator field circuit.

- Use a voltmeter to check that the battery voltage is between 12.4 and 12.6 volts.

- Measure the alternator’s output voltage; it should be between 13.5 and 14.5 volts when the engine is idling.

Understanding the P0625 Code

The P0625 code means that your vehicle’s powertrain control module (PCM) has found a problem with the generator field control circuit, which can often cause battery drain issues.

To fix this, you should focus on checking the generator and the electrical system. Start by closely inspecting the generator for any signs of wear or damage.

Use a voltmeter to check the battery voltage and make sure it’s within the right range. Next, do a detailed check of the electrical system to see if the wiring and connectors are in good shape.

Look for any signs of rust or bad connections that might be causing the problem. By keeping an eye on your generator and regularly checking the electrical system, you can avoid more problems and keep your vehicle’s electrical system working well.

Common Causes of P0625

The main reasons for the P0625 code are a bad generator and damaged wiring. A faulty generator can’t produce the right voltage, causing unusual readings.

Damaged wiring can mess with electrical signals, making it important to check and maintain the generator and wiring regularly.

Other reasons include a malfunctioning PCM, corroded connectors, and a weak battery.

Finding these problems early can save you money on repairs. Regular maintenance and careful checking of the electrical system can help keep your vehicle running smoothly and prevent the P0625 code from coming back.

Symptoms of P0625 Code

When you see the P0625 code, it usually comes with some clear signs that there’s an electrical problem. Catching these symptoms early can help you avoid bigger issues later.

Here are the common signs:

- Dashboard Warning Lights: Lights like the battery or check engine light come on, indicating electrical problems.

- Starting Problems: You might have trouble starting your car, and the battery might drain faster than usual.

- Electrical Issues: Things like lights, the radio, or power windows might not work properly or stop working altogether.

Risks of Ignoring P0625

Ignoring the P0625 code can lead to your battery completely failing and causing major damage to your car’s electrical system. If you don’t take care of your battery, it might drain quickly and leave you stuck somewhere.

Checking your car’s electrical system is very important because if there are issues you don’t fix, it could affect crucial parts like the ABS and traction control, which are vital for your safety. Ongoing voltage problems can make wiring issues worse and lead to expensive repairs.

Over time, your alternator and other electrical parts could get damaged beyond repair. Not fixing the P0625 code can also cause your car to stall suddenly, which is very dangerous, especially when driving fast.

Regular battery care and timely electrical checks are essential to avoid these serious problems and ensure your car stays reliable and safe.

Diagnosing the Generator Circuit

To figure out what’s wrong with the generator circuit, start by taking a good look at the generator field circuit for any signs of damage or wear. This is a crucial step in troubleshooting the generator and its electrical system. Check for frayed wires, loose connections, or any corrosion that could be causing issues.

Next, make sure all the generator’s connections are tight and secure. Finally, use a multimeter to measure the generator’s output to see if it’s producing the correct voltage.

Here’s a simple checklist:

- Check the Wiring: Look for any visible damage or corrosion.

- Secure the Connections: Ensure all terminals are tight and clean.

- Measure the Output: Use a multimeter to check the voltage levels.

Following these steps will help you quickly identify and fix any problems with the generator circuit.

Checking Battery Voltage

After checking the generator circuit, the next thing to do is check the battery voltage with a voltmeter to make sure the battery is giving enough power.

First, make sure the vehicle is turned off and the keys are out. Connect the voltmeter’s positive lead to the positive terminal of the battery and the negative lead to the negative terminal. A good battery should show between 12.4 and 12.6 volts. If the reading is lower, there might be an issue with the battery.

Regularly test the voltage to spot early signs of battery problems. Keeping your battery fully charged is important to prevent issues like the P0625 code and to ensure your vehicle’s electrical system works properly.

Regular checks can save you from expensive repairs.

Measuring Alternator Output

Checking your alternator’s output is important to make sure it’s producing the right voltage for your car’s electrical system and charging the battery properly.

Here’s how you can do it with a multimeter:

- Set the Multimeter: Switch it to measure DC voltage.

- Test at Idle: With the engine running, put the multimeter leads on the battery terminals. The reading should be between 13.5 and 14.5 volts.

- Rev the Engine: Increase the engine speed and check if the voltage stays within the same range.

Keeping the voltage steady is key to avoiding issues like the P0625 code.

This simple test can help you spot problems and ensure your car’s electrical system is working right.

Evaluating the PCM

Checking the PCM involves making sure it can properly communicate and control the alternator to maintain the right voltage levels in your car’s electrical system.

Start by testing the PCM to ensure it’s sending the correct signals to the alternator. Use a diagnostic scanner to look for software issues or outdated firmware. If there are any problems, you might need to update the software to fix the communication.

Make sure the PCM’s wiring is in good shape and not rusty. Check the connectors to ensure they’re securely connected.

Testing the PCM accurately not only finds problems but also tells you if a software update is needed, ensuring your car’s electrical system works well. This step is crucial before doing any other repairs.

Repairing Faulty Components

When fixing broken parts, start by swapping out the bad generator to get the right voltage and stop more electrical problems.

Here’s what you need to do for a good repair:

- Upgrade the Alternator: Think about getting a better alternator if the current one is old or not working well. This can make the system more stable and last longer.

- Check the Connectors: Look closely at the connectors for any rust or damage. Clean or replace any that are bad to keep a solid electrical connection.

- Test the System: After putting in the new generator and checking the connectors, test the whole electrical system to make sure everything is working right. This will help your vehicle run smoothly and avoid more problems.

Preventing P0625 Recurrence

After fixing the faulty parts, it’s important to take steps to prevent the P0625 code from coming up again.

Start by setting up a regular maintenance schedule. Include routine checks of the electrical system to spot any problems early.

Make sure to inspect and clean all electrical connections so they’re secure and free of rust.

Regularly check the battery voltage and alternator output using simple tools like a voltmeter and multimeter.

Watch the condition of the wiring and connectors, and replace any damaged parts quickly.

Keep a record of any error codes and use a diagnostic scanner for ongoing checks.

More OBD-II Codes

Frequently Asked Questions

Can I Fix the P0625 Code Myself Without Professional Help?

You can try to fix the P0625 code yourself if you know a bit about car electronics. Look at the wiring, check for signs like the battery draining, and use a multimeter to test the alternator and battery.

How Long Does It Typically Take to Repair the P0625 Code?

You might think fixing a P0625 code is quick, but the time it takes can vary. Depending on what’s needed, it could take a few hours or even a whole day, especially if there are wiring problems.

Are There Any Specific Tools Required to Diagnose the P0625 Code?

To figure out what’s causing the P0625 code, you’ll need some basic tools like a code reader to find the error, a multimeter to check electrical connections, and a voltmeter to test the battery. These tools will help you identify the problem in the generator field control circuit.

Does the P0625 Code Affect Fuel Efficiency?

When the P0625 code pops up, it can hurt your fuel efficiency. If the electrical system isn’t working well, your engine won’t run as efficiently, which means you’ll use more fuel and notice a drop in performance.

Can Extreme Weather Conditions Trigger the P0625 Code?

Extreme weather can cause the P0625 code to show up by messing with electrical systems. Cold weather can make the battery less efficient, and hot weather can cause wiring problems. Both of these issues can lead to unusual voltage readings that the powertrain control module picks up.

Conclusion

You can quickly fix the P0625 code problem by following a few simple steps.

First, check the generator field control for any obvious issues.

Then, measure the battery and alternator outputs accurately.

If you find any faulty parts, replace them.

Regular maintenance will keep your vehicle running smoothly and prevent future problems.

Stay on top of this now to avoid headaches later.