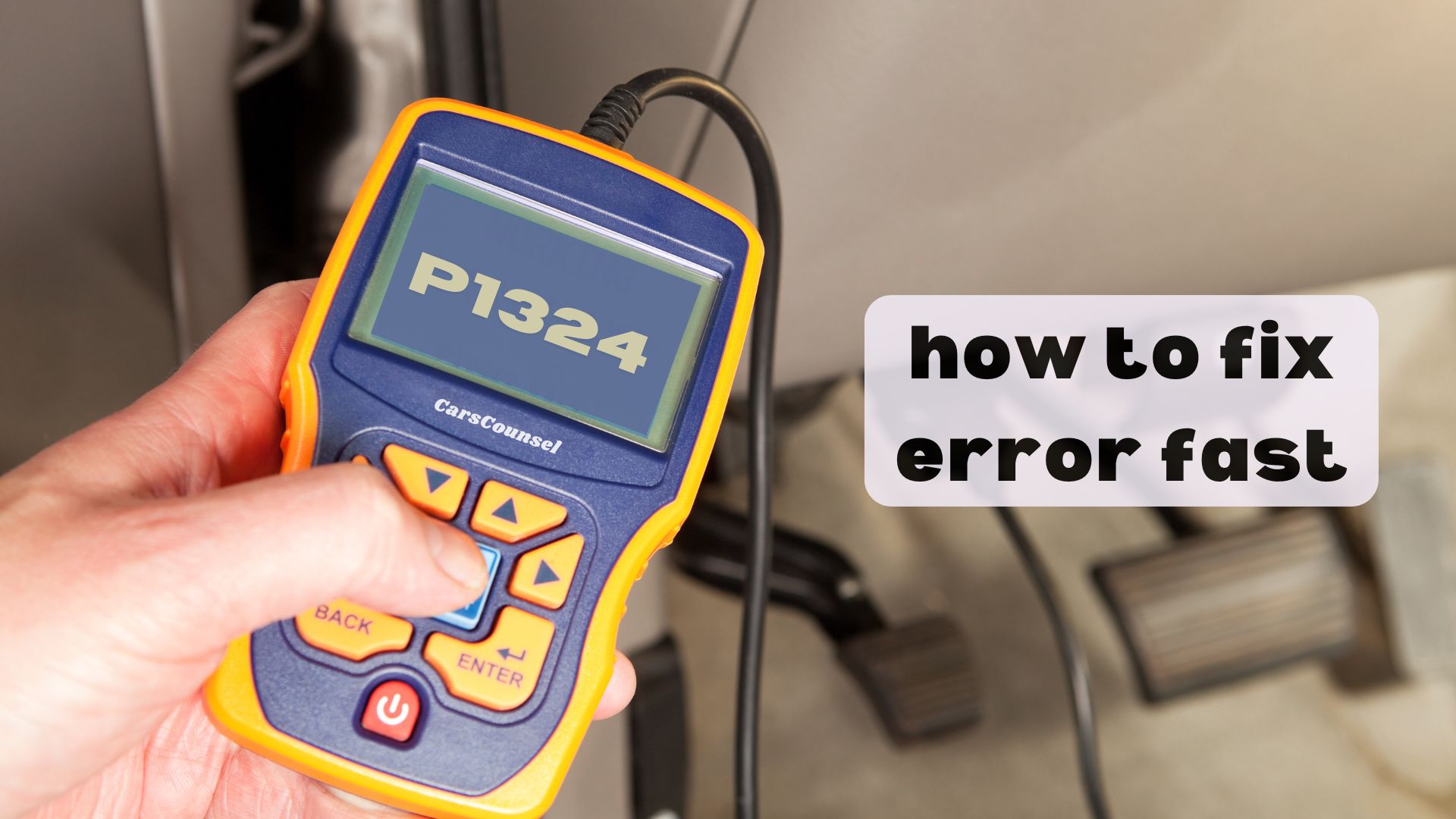

When your engine starts to knock, it’s like a ticking time bomb, warning you of impending doom. The P1324 code is that warning sign, indicating a low voltage condition in the knock sensor power source circuit. This critical issue can lead to decreased performance, poor fuel efficiency, and even engine damage. But what’s causing this electrical hiccup? Is it a faulty knock sensor or damaged wiring? You’ll need to investigate further to prevent your engine from going haywire.

Quick Navigation

Key Takeaways

- The P1324 code indicates a low voltage condition in the knock sensor power source circuit, affecting engine performance and potentially causing damage.

- Damaged wiring, faulty knock sensors, corrosion, and poor connections are common causes of the P1324 code.

- Symptoms include unusual engine noises, decreased performance, poor fuel efficiency, and rough idling or stalling.

- To fix the issue, diagnose the problem accurately, inspect the knock sensor circuit, and perform voltage checks to confirm correct power supply.

- Prevent future issues by guaranteeing proper installation and maintenance of the knock sensor circuit components.

Code P1324 Description

When your vehicle’s onboard diagnostic system flags a P1324 code, it’s indicating a low voltage condition in the knock sensor power source circuit.

This fault code alerts you to a vital issue affecting sensor functionality and engine performance.

The knock sensor detects abnormal combustion, sending a signal to the engine control module (ECM) to adjust ignition timing and prevent engine damage.

The ECM relies on accurate sensor data to optimize engine performance, so a faulty knock sensor can lead to decreased performance, poor fuel efficiency, and potentially even engine damage.

Common Causes of P1324

Damaged wiring or connectors in the knock sensor circuit are a common culprit behind the P1324 code.

When you’re dealing with this issue, you’ll want to investigate the root cause to prevent further damage.

- A faulty knock sensor can malfunction, leading to incorrect signals sent to the ECM, causing voltage fluctuations.

- Corrosion or poor connections in the wiring harness can disrupt the power source circuit, resulting in a low voltage condition.

- Sensor malfunctions or ECM issues can also trigger the P1324 code, so it’s essential to rule out these possibilities during your diagnosis.

Symptoms of P1324

What’s happening when your engine is producing unusual noises and performance issues?

You’re likely experiencing symptoms of the P1324 code. You may hear engine knocking or pinging noises, which can indicate a problem with your engine’s combustion process.

You’ll also notice decreased engine performance, poor fuel efficiency, and rough idling or stalling. The check engine light will likely illuminate, alerting you to the issue.

These symptoms can be frustrating, but identifying them quickly can help you address the underlying problem and prevent further engine damage.

How to Fix P1324

One crucial step in resolving the P1324 code is to diagnose the issue accurately.

You’ll need to identify the root cause of the problem to fix it effectively.

To do this, you’ll need to perform some checks, including:

- Inspecting the knock sensor circuit for signs of damage, corrosion, or poor connections

- Conducting voltage checks to confirm the sensor is receiving the correct power supply

- Performing sensor maintenance to guarantee the knock sensor is clean and free from debris

Diagnosing the Issue

Since the P1324 code indicates a low voltage condition in the knock sensor power source circuit, you’ll need to pinpoint the root cause of the problem to fix it effectively.

Start by using a scan tool to read the code and perform a visual inspection of the knock sensor circuit components.

Next, inspect the wiring harness and connectors for any damage, corrosion, or poor connections.

Perform sensor testing using a multimeter to verify the knock sensor is functioning correctly.

A thorough wiring inspection will help you identify any issues that may be contributing to the low voltage condition.

Repair and Replacement Costs

The cost to fix the P1324 code can vary widely depending on the root cause of the problem.

If you’re dealing with a faulty knock sensor, replacement costs can range from $100 to $300. However, if the issue lies with the wiring or connectors, repairs may only cost between $50 to $200.

- You may need to spend hours troubleshooting voltage fluctuations in the knock sensor circuit.

- Sensor maintenance is vital to prevent corrosion and poor connections.

- A blown fuse or short circuit can lead to more extensive and expensive repairs.

Troubleshooting the Knock Sensor Circuit

When diagnosing the P1324 code, you’ll need to scrutinize the knock sensor circuit to identify the root cause of the low voltage condition.

Start by performing a visual inspection of the circuit components, checking for signs of damage, corrosion, or poor connections.

Next, conduct sensor testing using a multimeter to verify the knock sensor is functioning correctly.

Perform circuit analysis to identify any electrical issues, such as a blown fuse or short circuit.

Preventing Future Issues

One crucial step in preventing future issues with the knock sensor circuit is to guarantee proper installation and maintenance of the components.

This includes conducting regular maintenance and proactive inspections to identify potential problems before they become major issues.

- Keep your vehicle’s wiring harness clean and free from corrosion to prevent electrical issues.

- Inspect the knock sensor and its connections regularly to verify they’re secure and functioning correctly.

- Monitor your vehicle’s performance and address any unusual noises or symptoms promptly to prevent minor issues from escalating.

More OBD-II Codes

| P1323 | P1322 | P1321 | P1320 |

| P1398 | P1315 | P1399 | P1405 |

| P1406 | P1407 | P1408 | P1409 |

| P1410 | P1415 | P1416 | P1418 |

| P1420 | P1421 | P1423 | P1431 |

| P1433 | P0016 | P0030 | P0031 |

Frequently Asked Questions

Can a Faulty Knock Sensor Cause Other Engine Problems?

You’ll likely experience engine performance issues if your knock sensor fails, as it can lead to sensor failure symptoms like misfires, decreased power, and poor fuel efficiency, ultimately impacting engine performance and potentially causing further damage.

Will a P1324 Code Trigger a Check Engine Light Immediately?

You’ll likely see the check engine light come on immediately if a sensor malfunction or faulty wiring in the knock sensor circuit triggers a low voltage condition, as the engine control module will detect the issue and illuminate the light to alert you.

Can I Drive My Car With a P1324 Code Safely?

“When in doubt, it’s better to err on the side of caution.” You can drive your car with a P1324 code, but beware of driving risks like engine knock or detonation. Keep a safe distance from other vehicles and monitor your car’s performance closely to avoid further damage.

Will a Tune-Up Fix a P1324 Code?

You’re wondering if a tune-up will fix the issue, but it’s unlikely. A tune-up typically focuses on spark plugs, air filters, and fuel injectors, not sensor issues or ignition timing adjustments, which are more likely to resolve the problem.

Can I Replace the Knock Sensor Myself?

Imagine being a detective searching for a tiny clue in a complex puzzle – that’s what replacing a knock sensor can feel like. You can do it yourself, but be prepared to locate the sensor (usually on the engine block or cylinder head), inspect the wiring, and guarantee proper connections.

Conclusion

As you rev up your engine, don’t let a faulty knock sensor power source circuit hold you back. By now, you’ve got the lowdown on code P1324 – it’s time to take the reins and get your ride running smoothly again. Remember, a stitch in time saves nine (or in this case, a timely repair saves your engine from damage). With the right diagnosis and fix, you’ll be shifting into high gear in no time.