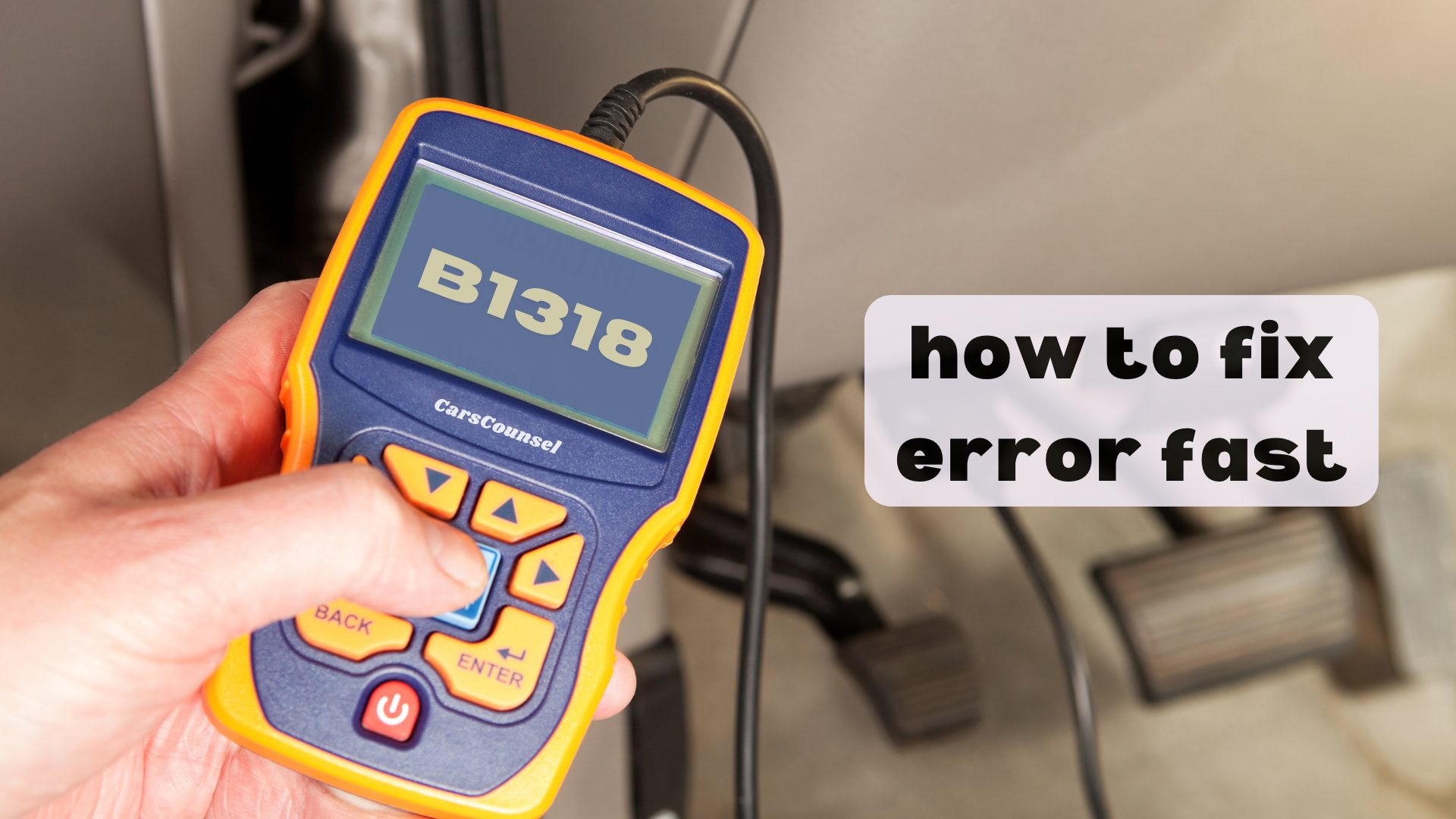

If you get a B1318 error code, it can be annoying, but fixing it quickly is important for safety.

First, use a diagnostic scanner to confirm the OBD2 error and find the problem in the passenger seatbelt circuit. The issue is usually caused by damaged wiring or rusty connectors, and sometimes a bad passenger seatbelt switch.

Once you figure out what’s wrong, replace the broken parts and clear the error code to get things working again.

But what if the problem doesn’t go away after doing all this?

Quick Navigation

Key Takeaways

- Plug in a diagnostic scanner to the OBD-II port to read and confirm the B1318 error code.

- Look over the seatbelt wiring and connectors for any damage or rust.

- Use a diagnostic scanner to check if the passenger seatbelt switch is working right.

- If needed, replace the broken seatbelt switch or fix any damaged wiring and connectors.

Understanding the B1318 Code

Understanding the B1318 code means knowing that there’s a problem with the passenger seatbelt circuit, which is a key part of your car’s safety system, including airbags and seatbelt pre-tensioners.

This code is important because it can affect how well your airbag works, which is crucial for passenger safety.

First, you should find the problem in the seatbelt circuit. This might involve broken sensors or damaged wires.

Use a diagnostic scanner to get specific error codes from your car’s computer.

Then, visually inspect the connectors and wiring for any noticeable damage or corrosion.

It’s important to diagnose this issue correctly to ensure that the airbag system works properly, keeping passengers as safe as possible.

Symptoms of the B1318 Code

When the B1318 code shows up, you’ll see the airbag warning light on your dashboard. This means there’s a possible problem with the passenger seatbelt system.

The warning light indicates issues that could affect seatbelt safety and airbag performance. This could result in the airbags not deploying correctly in an accident, which compromises passenger safety.

You might also notice that the seatbelt pre-tensioners aren’t working as they should. Ignoring this code can increase the risk in a crash.

It’s important to fix this issue right away to ensure that both the seatbelt and airbag systems work properly.

Common Causes of B1318

Several common issues can cause the B1318 code, which affects the passenger seatbelt system.

First, damaged wiring or connectors can result from regular wear and tear, impacting both seatbelt and airbag functionality.

Second, corroded connectors can interrupt electrical signals, causing safety systems to malfunction.

Third, a failed airbag control module, possibly due to manufacturing defects or physical damage, can make the airbag system stop working.

Lastly, software problems within the vehicle’s system can incorrectly trigger the B1318 code.

It’s crucial to diagnose and fix these problems quickly to ensure passenger safety. Each of these issues can compromise the reliability of the seatbelt and airbag systems, so they need immediate attention.

Faulty Passenger Seatbelt Switch

A broken passenger seatbelt switch can stop the car from recognizing when the seatbelt is fastened, causing the B1318 error code.

To fix this, first check if the switch is really broken. Use a diagnostic scanner to confirm the problem.

Once you know it’s the switch, disconnect the car battery to be safe. Find the bad switch, usually under the passenger seat.

Take out the old switch and put in a new one. Make sure all the connections are tight and reconnect the battery.

Finally, use the diagnostic scanner to clear the B1318 error code and test the system to make sure it’s fixed.

Check the seatbelt switch regularly to keep it working well.

Damaged Wiring Issues

Checking damaged wiring is key to fixing the B1318 code. Start by looking at the wiring insulation for any signs of wear or damage. Bad insulation can cause short circuits and mess up the circuit.

Here’s how to check and fix the wiring:

- Look Over Everything: Check for frayed wires, exposed copper, or melted insulation.

- Test the Circuit: Use a multimeter to make sure the circuit isn’t broken.

- Fix or Replace: Splice or replace damaged wires to get things working again.

- Check Connections: Make sure all connectors are firmly attached and not rusty.

Airbag Control Module Failure

Once you’ve checked for wiring problems, the next step is to see if the airbag control module might be broken.

Start by disconnecting the car battery to make sure the airbags won’t accidentally deploy. The airbag control module is typically located under the center console or dashboard. Take out the module and look it over for any obvious damage.

Then, use a diagnostic scanner to run a check on the module. If the scanner finds a problem with the module, you’ll need to replace it.

Put in the new module, reconnect the battery, and use the scanner to clear any error codes. Finally, do a system check to make sure everything is working correctly with the airbag system.

This step-by-step process helps ensure you effectively tackle one of the main causes of the B1318 code.

Corroded Connectors

Corroded connectors can mess up the electrical signals needed for the seatbelt system to work right. To fix this problem, follow these steps:

- Disconnect the battery: Always start by cutting power to avoid any electrical hazards.

- Check the connectors: Look for any signs of rust or damage that might be affecting the connection.

- Clean the connectors: Use an electrical contact cleaner to get rid of any rust and ensure a clean connection.

- Prevent future rust: Apply dielectric grease to the connectors to stop rust from forming again and ensure long-term reliability.

Following these steps will help keep your vehicle’s seatbelt system working properly and reduce the risk of seeing the B1318 code again.

Regular maintenance and checks can go a long way in keeping your car safe.

Diagnostic Tools and Steps

To accurately diagnose the B1318 code, you’ll need to use a diagnostic scanner to get the trouble codes from your vehicle’s computer. Make sure your scanner can show real-time data and interpret codes.

Here’s how to start:

- Connect the scanner to the OBD-II port in your car.

- Retrieve and write down all the trouble codes.

- Inspect the seatbelt wiring and connectors for any visible issues.

- Use the scanner to check the passenger seatbelt switch.

- Look up the specific steps for the B1318 code in your car’s service manual.

These steps will help you find the problem more quickly and make the repair process easier.

Repair and Replacement Solutions

If your diagnostics show the passenger seatbelt switch is faulty, you’ll need to replace it. Here’s how:

- Replace the Seatbelt Switch: First, disconnect the battery. Then, take out the seatbelt assembly and put in the new switch.

- Check Wiring and Connectors: Look for any wires or connectors that are damaged, frayed, or corroded. Fix or replace them if needed.

- Replace the Airbag Control Module: If the diagnostics show a problem, take out the old module and put in a new one, following the manufacturer’s instructions.

- Clear the Error Code: Use a diagnostic scanner to clear the B1318 code. Run a system check to make sure everything is fixed.

Following these steps will help you address all possible issues.

Preventive Maintenance Tips

Regularly check and maintain the seatbelt system to ensure everything works well.

Start with routine inspections: look for frays in the seatbelt webbing and make sure the buckle clicks securely.

Then, do some safety checks: buckle and unbuckle the seatbelt to see if the warning light works properly.

Check the wiring and connectors for any wear, corrosion, or damage.

Clean any corroded connectors and replace damaged parts right away.

Follow the manufacturer’s maintenance schedule, especially for seatbelt and airbag systems.

Consistent preventive maintenance lowers the chance of getting the B1318 code and ensures your vehicle’s safety features work reliably.

Stay proactive to avoid expensive repairs and keep passengers safe.

More OBD-II Codes

Frequently Asked Questions

How Long Does It Take to Diagnose the B1318 Code?

It usually takes about 1-2 hours to figure out the B1318 code. You’ll need to use diagnostic tools to get the error codes, then do things like look over the vehicle, test its parts, and check its history to make sure you get an accurate diagnosis.

Can I Drive With the B1318 Code Active?

You might be asking, ‘Can I drive with the B1318 code active?’ The answer is serious. Driving isn’t safe because your airbags might not work. Fix the issue right away to make sure your car’s safety systems are working properly.

What Is the Cost of Fixing the B1318 Code?

Fixing the B1318 code can cost anywhere from $100 to $500. The price depends on whether you do it yourself or hire a professional. The final cost will also depend on what needs to be fixed, such as sensors or wiring.

Are There Any Recalls Related to the B1318 Code?

Look up your vehicle’s recall history to see if there are any recalls related to the B1318 code. Car makers issue recalls when they find safety problems, like issues with airbags or seatbelts. Get in touch with your dealer for more information.

Can Aftermarket Parts Cause the B1318 Code?

Yes, aftermarket parts can cause the B1318 code because they might not be fully compatible. Use diagnostic tools to identify any problems. Make sure all parts match the manufacturer’s specifications to avoid triggering the error code.

Conclusion

In short, to quickly fix the B1318 code, you need to be both accurate and fast.

Start by using a diagnostic scanner to find the problem.

Then, carefully check the wiring and connectors to make sure you don’t miss anything.

If the seatbelt switch is faulty, replace it to keep things safe.

After making the repairs, clear the error code and run a system check to ensure everything is working well.

Being thorough yet quick will ensure the job is done right and efficiently.