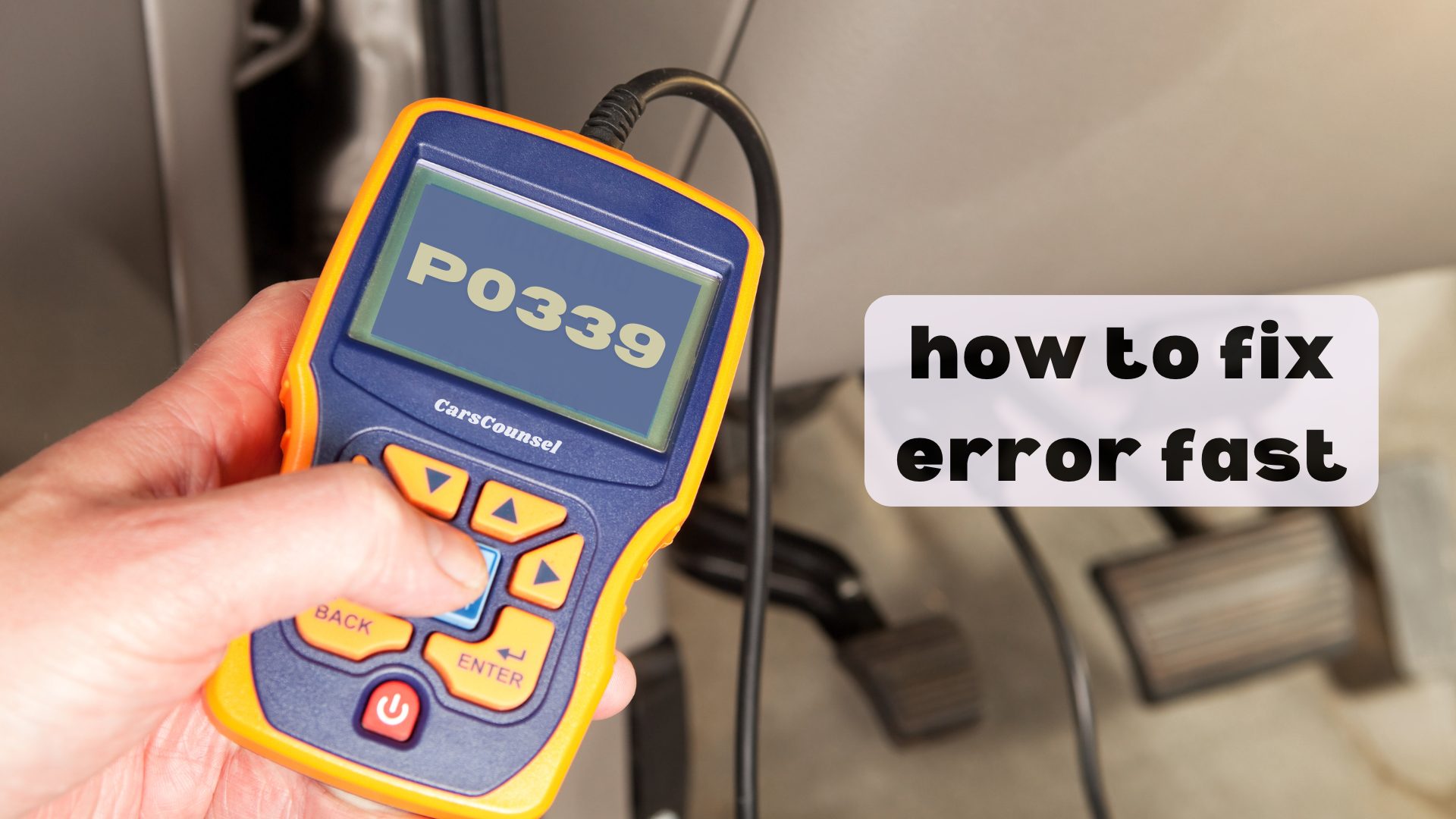

Figuring out the P0339 code for a crankshaft position sensor error can be pretty straightforward.

First, use a diagnostic scan tool to confirm the error and check for any related codes.

Next, take a look at the crankshaft position sensor and its wiring for any obvious damage or loose connections. If you spot any problems, fix or replace the sensor and make sure all the wiring is secure.

Also, don’t forget to test the sensor’s output and clear the error codes to make sure everything is working properly again.

Quick Navigation

Key Takeaways

- Check the Crankshaft Sensor: Look at the crankshaft position sensor and its wiring to see if there’s any damage or loose connections.

- Use Diagnostic Tools: Use a scan tool to confirm the P0339 code and check the sensor’s signal.

- Check Timing Parts: Make sure the timing belt or chain is in good shape and not affecting the sensor.

- Replace a Bad Sensor: If the sensor is broken, replace it quickly to get the engine working right.

What Is the P0339 Code?

The P0339 code is part of a larger OBD2 Codes which means means there’s a problem with the crankshaft position sensor, which is important for keeping track of how fast the crankshaft is spinning and its position.

This sensor is key for making sure the engine fires at the right time and gets the right amount of fuel. If the sensor is broken or its wiring is messed up, the engine won’t run well.

You should check the sensor and its wiring for any visible damage or wear. If the sensor isn’t sending the right signals to the engine control module (ECM), it can cause the engine to run poorly.

Fixing this issue quickly helps keep your engine running smoothly and avoids bigger problems down the road.

Don’t ignore this code; it’s important to check it out and fix it right away to keep your car in good shape.

Symptoms of P0339 Code

When dealing with a P0339 code, you’ll notice things like engine misfires, stalling, and the check engine light coming on. Spotting these symptoms is crucial for fixing the issue quickly.

You might also have trouble starting the engine or find that it runs roughly. These signs point to a problem with the crankshaft position sensor. Pay attention to any changes in how the engine runs, as these can show how bad the problem is.

If the engine keeps stalling or misfiring, it means the sensor isn’t sending the right signals to the engine control module. Act fast to diagnose and fix the sensor problem to avoid more damage and keep your engine running smoothly.

Common Causes of P0339

Finding out why you’re getting a P0339 code can help you fix the problem quickly and avoid more engine damage.

Start by checking the crankshaft position sensor, as it’s often the main cause. If the sensor is broken or worn out, you’ll need to replace it.

Next, take a good look at the wiring. Look for any damaged or loose connections that might be messing with the sensor. Also, make sure the sensor is well-sealed to keep out moisture, which can cause problems.

Check the timing belt or chain too, as issues there can affect the sensor.

Although it’s rare, a bad engine control module (ECM) could also cause this code.

Impact on Engine Performance

If you get a P0339 code, your engine’s performance can take a big hit, causing issues like misfires, stalling, and lower fuel efficiency.

This happens because the crankshaft position sensor isn’t sending the right signals to the engine’s computer. This throws off the engine’s timing and fuel injection, making it run poorly.

To keep your engine running well, you need to fix this issue right away. Check the sensor and its wires for any damage and replace any bad parts.

Regular maintenance and quick repairs will keep your engine stable and your car running smoothly. Ignoring this problem can make things worse and lead to more expensive repairs later.

Affected Car Models

Some car models, like the Honda Civic, Subaru Impreza, Ford Focus, Dodge RAM, and Chevrolet Silverado, are more likely to have issues with the crankshaft position sensor. This can lead to problems with how the car runs. If you own one of these cars, keep an eye out for signs that the sensor might be failing to avoid bigger issues.

Honda Civic: Known for engine stalling because of sensor issues.

Subaru Impreza: Often has trouble starting due to sensor problems.

Ford Focus: Performance can get worse because of sensor faults.

Dodge RAM: Some model years have unreliable sensors.

Chevrolet Silverado: Sometimes has sensor problems that affect engine performance.

Diagnosing the P0339 Code

To figure out the P0339 code, start by using a scan tool to read the error code and see how serious it is.

First, test the crankshaft position sensor to ensure it’s sending the right signal to the engine control module (ECM). Look at the sensor and its wiring for any visible damage or wear.

Use diagnostic tools to check for other related codes that might point to bigger problems. Assess the engine’s performance and watch how the vehicle behaves for more clues.

Be sure to visually inspect the timing belt or chain, as problems here can affect the sensor’s function.

Following these steps will help you accurately diagnose the issue and prevent further complications.

Inspecting the Crankshaft Sensor

When checking the crankshaft sensor, start by disconnecting the battery to stay safe and avoid electrical problems. Use your vehicle’s manual to find the exact location of the sensor. Once you find it, look at the sensor and its connections to see if there are any signs of damage or wear and tear.

Next, follow these steps:

- Check the sensor’s connector: Make sure it’s clean, not rusty, and firmly connected.

- Test sensor resistance: Use a multimeter to measure the resistance and compare it to the numbers in the manual.

- Inspect the mounting: Ensure the sensor is properly aligned and securely attached.

- Perform a signal test: Use a scan tool to check if the sensor is sending the correct signals.

These steps will help you find and fix any issues with the crankshaft sensor.

Fixing Wiring Issues

After checking the crankshaft sensor, focus on fixing any damaged or loose wires to ensure the sensor works properly.

Start by thoroughly examining the wiring. Look for frayed wires, rust, or loose connections. Use a multimeter to check if the wires are continuous and ensure there are no breaks in the circuit.

Secure any loose connectors and replace any damaged wires right away. Make sure all connections are clean and tight to ensure accurate data transmission.

Inspect the wiring insulation to prevent short circuits. After making repairs, clear the error code using a scan tool and take the vehicle for a test drive to confirm the problem is fixed.

Regularly check the wiring as part of your vehicle’s maintenance routine.

Replacing the ECM

Replacing the ECM

Since ECM failure isn’t common, it’s important to be sure that it’s the problem when you see the P0339 code.

Here’s how to replace the engine control module step-by-step:

First, make sure the ECM is really the issue. Disconnect the battery to avoid any electrical problems. Be careful when handling the ECM to avoid any static discharge that could damage it.

Once you’ve installed the new ECM, you’ll need to reprogram it to fit your vehicle’s settings.

Here’s a simple checklist:

- Disconnect the battery to avoid electrical issues.

- Remove the old ECM carefully to prevent static discharge.

- Install the new ECM properly.

- Reprogram the new ECM to make sure it works with your vehicle.

Follow these steps to replace your ECM and clear the P0339 code.

Professional Repair Costs

The cost to fix the P0339 code can vary a lot depending on what’s wrong and your car’s model. On average, the crankshaft position sensor part costs between $50 and $250. Labor costs usually range from $100 to $200 per hour, depending on the service center. You might also have to pay a diagnostic fee, which can be between $50 and $100.

| Service Task | Estimated Cost | Notes |

|---|---|---|

| Crankshaft Sensor | $50 – $250 | Part only |

| Labor | $100 – $200 per hour | Varies by shop |

| Diagnostic Fee | $50 – $100 | Initial assessment |

For accurate estimates, check with your local mechanic or dealership. Fixing the issue promptly can prevent more engine damage and keep your car running well.

More OBD-II Codes

Frequently Asked Questions

Can Driving Long Distances Worsen the P0339 Code Issue?

Driving long distances can make the P0339 code problem worse. The longer you drive, the more stress you put on the engine, which can make sensor issues worse. This can lead to bigger problems like engine misfires, stalling, and even damage to other engine parts.

Are Aftermarket Sensors Reliable for Fixing the P0339 Code?

Yes, the quality of aftermarket sensors can differ. Make sure you buy from well-known brands. When installing the sensor, follow these steps carefully: check the wiring, ensure connections are secure, and verify the signal is working correctly. Proper installation is key to fixing the P0339 code and ensuring the sensor works reliably.

How Long Does It Take to Replace a Crankshaft Position Sensor?

Replacing a crankshaft position sensor usually takes about an hour if everything goes smoothly. Just gather your tools, make sure you install the sensor correctly, and cross your fingers there’s no hidden damage.

Can a Failing Crankshaft Position Sensor Affect Fuel Efficiency?

Yes, a bad crankshaft position sensor can hurt your fuel efficiency. This sensor is crucial for your engine’s timing. When it starts to fail, you might experience misfires and stalling, which can cause your car to use more fuel and perform worse.

What Preventive Measures Can Be Taken to Avoid the P0339 Code?

Think of your engine running smoothly like a well-played symphony. To keep it that way, perform regular maintenance and calibrate sensors on time. Check the wiring, inspect the connections, and replace any worn-out sensors to prevent the P0339 code and ensure your engine runs smoothly.

Conclusion

Fixing the P0339 code quickly can save you from expensive repairs and make your car run better.

Did you know that bad crankshaft position sensors cause over 30% of engine problems? Don’t ignore the signs.

Use a diagnostic tool to check the sensor and wiring, and replace any bad parts.

If the problem doesn’t go away, talk to a professional.

Acting fast ensures your engine runs smoothly and efficiently.